HE

1780

.A33

no.

91/03

WASHINGTON,

DC.

20594

RAILROAD ACCIDENT REPORT

ATCHISON, TOPEKA AND

SANTA FE RAILWAY COMPANY (ATSF)

FREIGHT TRAINS ATSF 818 AND ATSF 891

ON THE ATSF RAILWAY

CORONA, CALIFORNIA

NOVEMBER 7, 1990

n i- -

AW'

<3//o3

NTSB/RAR-91/03

PB91-916303

NATIONAL TRANSPORTATION

SAFETY

BOARD

WASHINGTON, D.C.

20594 !

i;

RAILROAD

ACCIDENT

REPORT

ATCHISON,

TOPEKA

AND

bANTA

FE

RAILWAY

COMPANY

(ATSF)

FREIGHT

TRAINS

ATSF

818 AND

ATSF

891

ON THE

ATSF

RAILWAY

CORONA,

CALIFORNIA

NOVEMBER

7

f

1990

ADOPTED:

July

23,1991

NOTATION:

5413A

Abstract:

This report explains the collision between two

Atchison,

Topeka and Santa

Fe

Railway freight trains in Corona, California, on November 7, 1990 Among the

safety

issues

discussed

are the following. effect of work/rest

cycles

on performance,

crashworthiness

of event recorders and locomotives, fuel tanks, positive train

separation,

company's method of detecting drug use by its employees, company's

method of notifying pipeline operators of accidents, need to develop simplified

format for work-record data collected by rail carriers, and need to develop policy

blocking employees from working if they lack sleep

The National Transportation Safety Board

is an

independent Federal agency

dedicated

to

promoting

aviation, railroad, highway, marine, pipeline,

and

hazardous materials safety Established

in 1967, the

agency

is

mandated

by the

Independent Safety Board

Act of 1974 to

investigate transportation accidents,

determine

the

probable cause

of

accidents, issue safety recommendations, study

transportation safety

issues,

and

evaluate

the

safety effectiveness

of

government

agencies

involved

in

transportation

The

Safety Board makes public

its

actions

and

decisions

through accident reports, safety studies, special investigation reports,

safety recommendations, and statistical reviews

Information

about available publications may

be

obtained

by

contacting:

National Transportation Safety Board

Public

Inquiries Section, RE-51

800

Independence Avenue, S.W.

Washington,

D.C.

20594

(202)382-6735

Safety

Board publications

may be

purchased,

by

individual copy

or by

subscription,

from:

National Technical

Information

Service

5285

Port Royal Road

Springfield, Virginia

22161

(703)487-4600

CONTENTS

EXECUTIVE

SUMMARY

INVESTIGATION

Accident }• ^

Injuries

Damages

Crew

Information

ATSF818

Engineer

Conductor

ATSF891

Engineer

Conductor

Train

Information

General

ATSF818

ATSF891

Track and Signal

Information

Track

Signal

Radio

Operational

Information

Work/Rest Cycles

Operations .. .

Meteorological

Information

Medical and Pathological

Information

ATSF

818

Engineer ...

Conductor

Brakeman

ATSF891

Engineer ...

Conductor

Brakeman

Injuries

Fatal •

Survivors

Toxicology for Drug Testing

Drug Policy

Fire

Postaccident Damage Examination — ...

Survival

Aspects •

Emergency Response

Crashworthiness

Pipeline

Information

Natural Gas Pipeline

Petroleum Pipeline

Tests and Research

Sight Distance .

Signal

System

iii

Event

Recorders 28

Natural Gas Pipeline 29

Petroleum Pipeline 29

Other

Information

29

Pipeline Notification 29

Locomotive Fuel Tank 29

Positive

Train Separation System 30

ANALYSIS

General 30

Accident 30

Work/Rest Cycles 31

Engineer of

train

818 31

Conductor of

train

818 35

Brakeman of

train

818 35

Behavioral Actions of the Crew of Train 818 36

Acceptance of Work Assignment 37

Positive

Train Separation 40

Pathological 41

Drug Issue 42

Conductor of

train

891 , 42

Engineer of

train

891 42

Work Records 43

Locomotive Crashworthiness 43

Fuel

Tank Crashworthiness 44

Event

Recorders • 44

Notification of Pipeline Operators 45

CONCLUSIONS

Findings 45

Probable Cause 46

RECOMMENDATIONS

46

APPENDIXES

Appendix A-lnvestigation and Hearing ... 49

Appendix B-Personnel

Data

51

Appendix C-Rules Applicable to this Report .. 53

Appendix

D-Notification

Form Used by

ATSF

for Pipeline Operators 55

Appendix

E--ATSF

Drug Policy 57

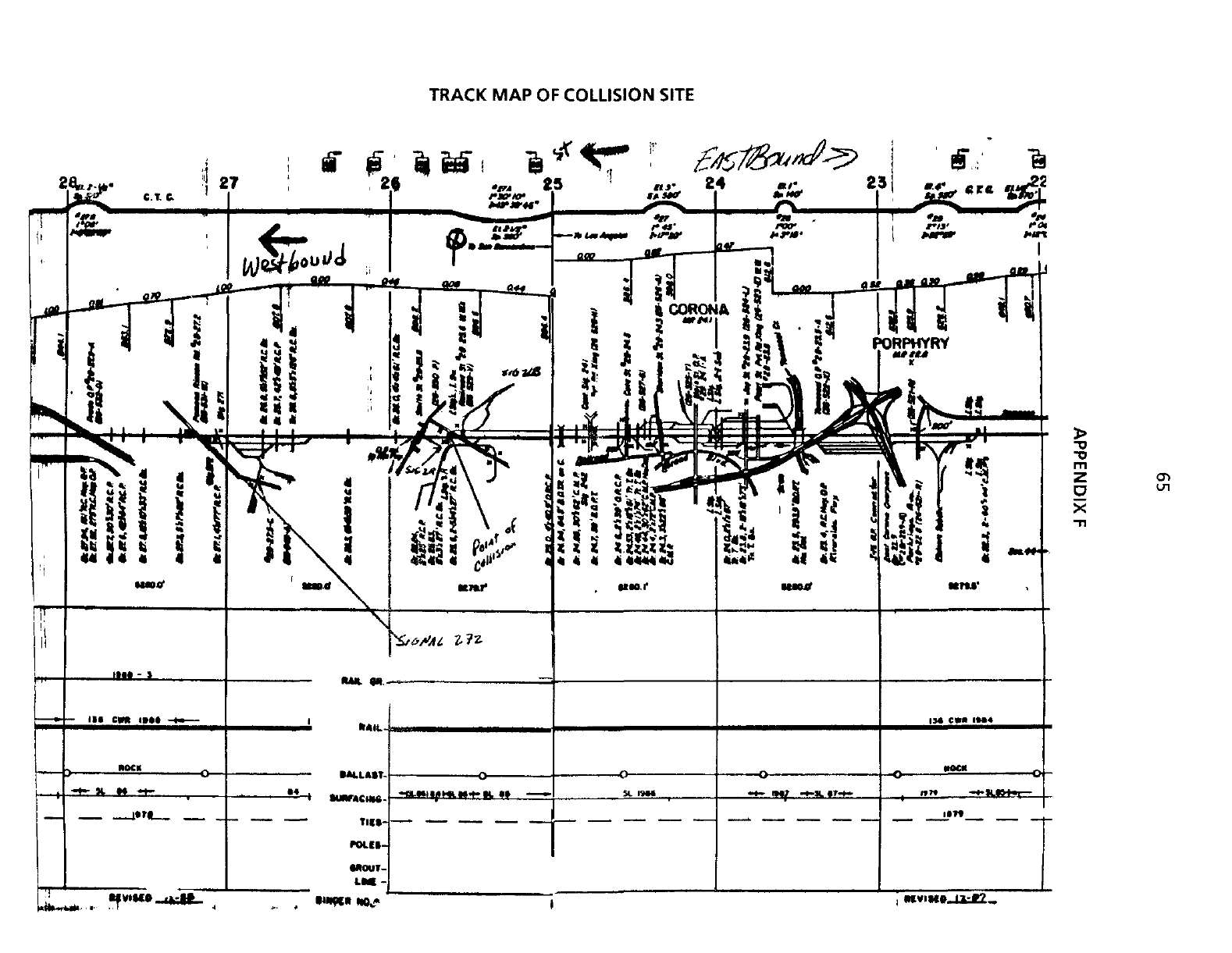

Appendix F-Track Map of Collision Site — . 65

iv

iXECUTIVE SUMMARY

On

Wednesday,

November 7, 1990, about 4 11am

Pacific

standard time, two

Atchison,

Topeka

and

Santa

Fe

Railway

Company

(ATSF)

freight

trains collided head

on at milepost

(MP)

25.6 in Corona, California. The westbound

ATSF

freight

train

818, which was traveling

from

Barstow, California, to Hobart yard, City of

Commerce,

California, was on the Corona siding It passed the stop signal, and the

lead

locomotive reentered the main track

area,

blocking all movement on the main

track The eastbound

ATSF

freight

train

891, which was traveling

from

Hobart yard

to

Chicago,

Illinois, was on the main track and collided

with

train

818.

Each

train

had

three-person crews

As

a result of the collision, the entire crew of

ATSF

818 was

killed

and

four

locomotives and three rail

cars

were derailed The engineer and conductor of

train

891 sustained serious injuries and the brakeman was killed, all three locomotives

and

five rail

cars

were derailed The

total

damage was estimated to be $4,400,000.

The

major safety

issues

addressed

in the report are

o

Effects of the

Crew's

Work/Rest

Cycle

on Performance

o

A Drug Policy Follow-Up

Issue

o

Crashworthiness of

Event

Recorders

in an Accident

The

National Transportation

Safety

Board determines that the probable

cause

of the collision was the failure of the engineer of

train

818 to stop his

train

at the

stop signal because he was asleep Contributing to the accident was the failure of

the conductor and the brakeman to take action, probably because they too were

asleep,

to stop the

train

Also

contributing

to the accident were the irregular

unpredictable work schedule of the engineer on

train

818, the Atchison, Topeka and

Santa

Fe

Railway

Company's lack of a policy or procedure for removing

crewmembers

from

service when they are not fit for duty because of a lack of sleep,

and

the inadequacy of the Federal rules and regulations that govern hours-of-

service

As

a result of its investigation, the

Safety

Board issued recommendations to the

Atchison,

Topeka and

Santa

Fe

Railway

Company, the Federal Railroad

Administration, the California Public Utilities Commission, the California

State

Fire

Marshal,

the Brotherhood of Locomotive Engineers, the United I ransportation

Union,

and the Association of American Railroads.

v

NATIONAL

TRANSPORTATION SAFETY BOARD

WASHINGTON, D.C.

20594

RAILROAD

ACCIDENT

REPORT

COLLISION

OF

ATCHISON, TOPEKA AND

SANTA

FE

RAILWAY COMPANY (ATSF)

FREIGHT

TRAINS ATSF

818 AND

ATSF 891 ON THE ATSF RAILWAY

CORONA, CALIFORNIA

NOVEMBER

7,1990

INVESTIGATION

Accident

On

November 6, 1990, at 10.15 p m.

Pacific

standard time, the crewmembers

on the Atchison, Topeka and

Santa

Fe

Railway

Company

(ATSF)

freight

train

818

went on

duty

at

their

away-from-home terminal in Barstow, California. Train 818

was

a westbound cabooseless

freight

train

originating

in Barstow and destined for

Hobart yard in the City of

Commerce,

California. The

train

consisted of 5 locomotives

and

91

rail

cars

(74 were loaded and 17 were empty) It had 8,616

trailing

tons and

was

5,996

feet long

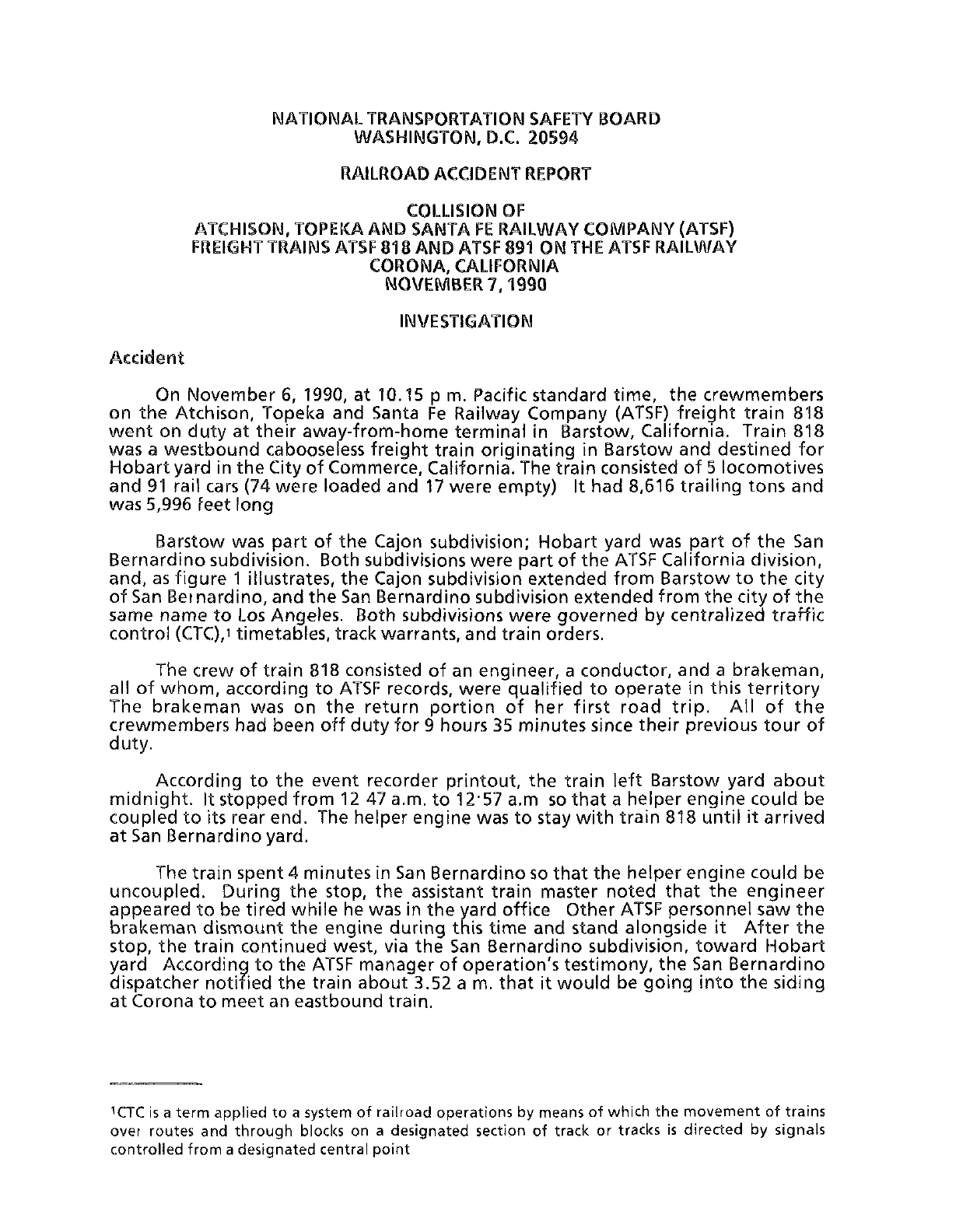

Barstow

was part of the Cajon subdivision; Hobart yard was part of the San

Bernardino subdivision. Both subdivisions were part of the

ATSF

California division,

and,

as

figure

1

illustrates, the Cajon subdivision extended

from

Barstow to the city

of

San

Bernardino, and the

San

Bernardino subdivision extended

from

the city of the

same

name to Los Angeles. Both subdivisions were governed by centralized

traffic

control

(CTC)J

timetables, track warrants, and

train

orders.

The

crew of

train

818 consisted of an engineer, a conductor, and a brakeman,

all of whom, according to

ATSF

records, were qualified to operate in this

territory

The

brakeman was on the

return

portion

of her

first

road

trip.

All of the

crewmembers

had been off

duty

for 9 hours 35 minutes since

their

previous

tour

of

duty.

According to the event recorder

printout,

the

train

left

Barstow yard about

midnight.

It stopped

from

12 47 a.m. to 12*57 a.m so that a helper engine could be

coupled to its rear end. The helper engine was to stay

with

train

818

until

it arrived

at

San

Bernardino yard.

The

train

spent 4 minutes in

San

Bernardino so that the helper engine could be

uncoupled. During the stop, the assistant

train

master noted that the engineer

appeared

to be

tired

while he was in the yard office Other

ATSF

personnel saw the

brakeman dismount the engine

during

this time and stand alongside it After the

stop, the

train

continued west, via the San Bernardino subdivision, toward Hobart

yard According to the

ATSF

manager of operation's testimony, the

San

Bernardino

dispatcher

notified

the

train

about 3.52 a m. that it would be going

into

the siding

at Corona to meet an eastbound train.

1CTC

is a term applied to a system of railroad operations by means of which the movement of trains

over

routes and

through

blocks on a designated section of track or tracks is directed by signals

controlled

from

a designated central

point

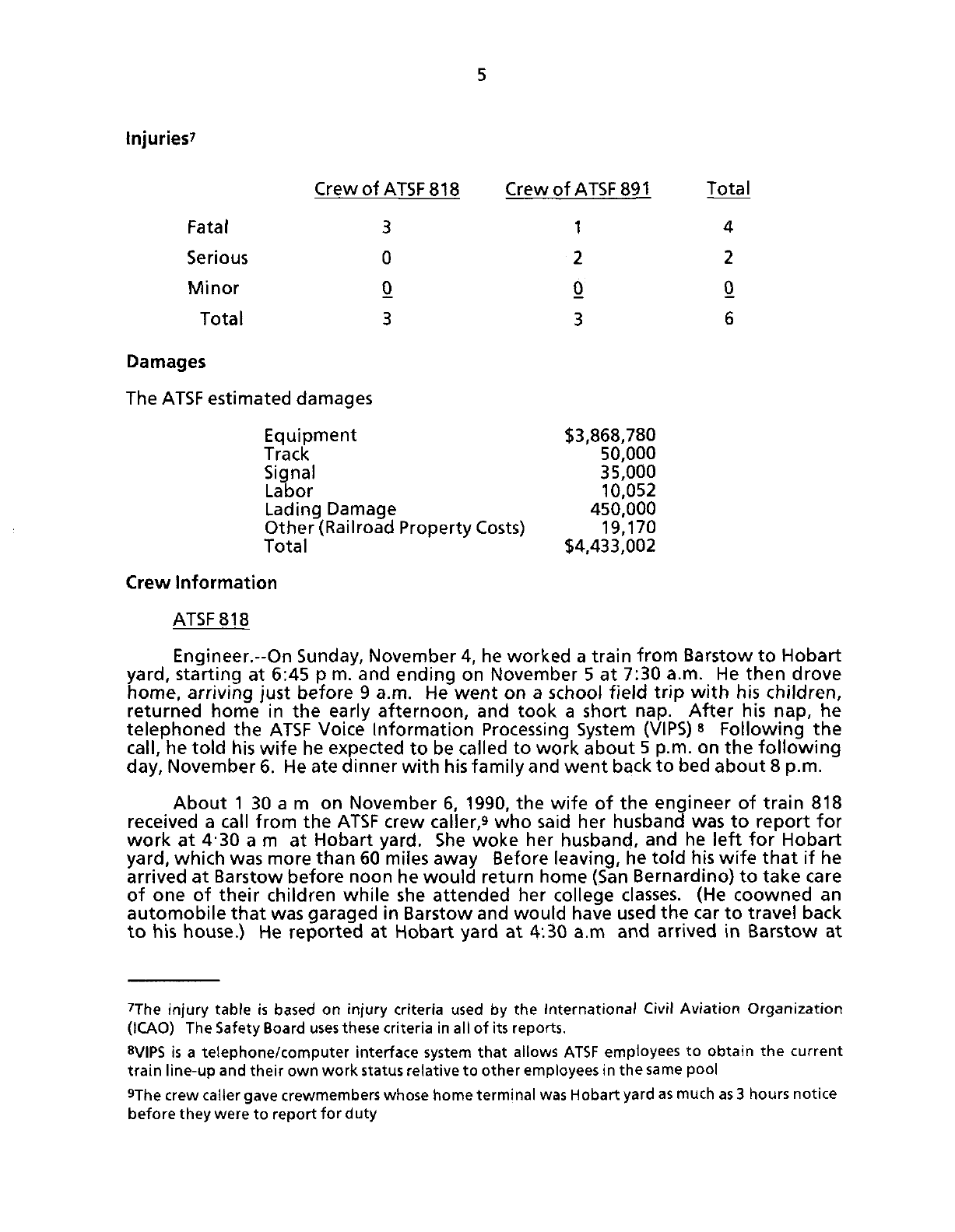

LOS ANGELES

t J

MILES

—

HOBART VARD

3 5.!

MILES

—

PRADO DAM

5 J

MILES

—

CORONA

14 3

MILES

RIVERSIDE

».7

MII.ES

SAN BERNARDINO

_

IS.6

MILES

—

SUMMIT

-

6 3.4

MILES

—

BARSTOW

Map

of

the

Atchison,

Topeka

and

Santa

Fe

Railway

Main Track

System

From Los Angeles, California

To

Barstow

California

Barstow

MP 745.9

Enlarged Area

"3,

San

Bernardino

Subdivision

Los

Angeles

Starting Terminal'

for train 891

Starting terminal

for train 818

Pasadena

Branch

San

Bernardino

Distances

of

Grade Crossings from

the East Switch Of The Corona

Siding

•

Main Street 565 Feet

Sheridan Street 1,786 Feet

Cota Street 2,914 Feet

Railroad Avenue 8,272 Feet

Ah-

Collision Site

[]At Corona,

CA.

Industrial Siding

Four

Cwnrr3^^

Pipe Company

Petroleum

Lint

ATSF Main Track

Map Produced by

NTSB

Map Not

To

Scale

Figure

1

~

Map

of

the Atchison, Topeka and Santa Fe Railway

main track system

from

Los

Angeles

to

Barstow

3

According

to the event recorder printout, when the train approached the east

end of the Corona siding, its speed was gradually reduced by the dynamic braking

system.

When the train entered the siding, there was a reduction of air pressure in

the automatic air brake3 system of 6 pounds, which retarded the train's speed to

15 mph, a speed that was in compliance with the maximum speed for this turnout.

When

the train was through the switch, the automatic air brake was released, and

the dynamic braking maintained the train's average speed of 14 mph until it reached

the vicinity of the Cota Street grade

crossing.

The wayside signal log showed that

the train was clear of the main track at 4:08 a m

A

security guard on the north side of the Corona siding in an industrial area

saw

and heard the train as it sounded its horn and

crossed

the Sheridan Street grade

crossing

When the lead locomotive passed him, he saw a male figure sitting with his

back

to the engineer's window; the window was open, and the interior dome light

on

the engineer's side was on.

The guard was a railroad enthusiast and wanted to take a photograph of two

trains meeting in the night. He thought that since this train was in the siding, a

meeting would occur at Railroad Avenue Once the train cleared the grade

crossing,

he

drove toward Railroad Avenue, where he intended to take his pictures. He

testified that en route to Railroad Avenue his automobile windows were open and

he

heard the train's horn sound for the Cota Street grade

crossing.

The dwarf signal on the west end of the siding displayed a red "stop" aspect

when

train 818 entered the siding The signal log shows that about 4.10 a m the

section

of track past the stop signal was occupied. About 4-11 a.m. an emergency

brake application*

was

made, according to the event recorder

s

No other trains were

in the siding at the time. Train 818 came out of the siding; the lead locomotive

blocked the main track, and obstructed eastbound traffic. The head end of the lead

unit was positioned over the frog at impact The train remained in this position

throughout the collision. All three crewmembers dismounted the train and

attempted to flee the area During their attempt all of them were consumed by a

fireball, which ignited afterthe collision.

On

November 7, at 2 a.m., the crewmembers of train 891 went on duty at

Hobart

yard,

their home terminal The train was an eastbound cabooseless

trailer-on-flatcar train, which originated at Hobart yard and was en route to

Chicago,

Illinois. The crew was scheduled to operate the train only between Hobart

2Dynamic

braking

is a

method

of

train

braking

whereby the

kinetic

energy of a

moving

train

is used

to generate

electric

current

at the

locomotive

traction

motors,

which

is

then

dissipated

through

banks

of

resistors

in the

locomotive

car

body

3An

automatic

air

brake

is a

braking

system

that

draws air

from

the

atmosphere

and

stores

it

under

pressure A

reduction

in

brake

pipe

pressure, regardless of how it is

initiated

(bleeding

of air by use of

a

valve or by a

break

in the

train

line),

automatically

applies

the brakes An increase in

brake

pipe

pressure causes brakes to release

4An emergency

brake

application

is a

substantial

reduction

of

brake

pipe

pressure made when a

train

must

be

stopped

in the

minimum

distance

possible

An emergency

application

may also occur when a

brake

pipe

is

broken

or when air hoses between cars are

disconnected

with

angle cocks

open

An

emergency

application

can be

initiated

by any

crewmember

5The event

recorder

clock

and the

signal

log

clock

were not

synchronized.

4

yard and Barstow. The train had 3 locomotives and 47 rail

cars

(all loaded). It

weighed 3,150 trailing tons and

was4,229

feet long.

The crew of train 891 consisted of an engineer, a conductor, and a brakeman,

according to

ATSF

records, all were qualified to operate in this territory.

The engineer of train 891 talked with Safety

Board

investigators after the

accident but refused to speak to the Safety

Board

during deposition proceedings In

his

testimony the conductor took no exception to the engineer's handling of the

train during theirtourof duty.

The conductor stated that he and the engineer were in the lead (eastmost)

controlling locomotive and that the brakeman was in the second locomotive. The

brakeman, according to the conductor's testimony, chose of his own volition to ride

in the second unit.

The conductor further stated that as the train approached Corona, the CTC

signals

were displaying aspects^ permitting it to proceed eastward When the train

reached signal 2R (located at the west end of the Corona siding and governing

eastbound traffic on the main track), the aspect changed from a yellow "approach"

indication to a green "clear" indication. The yellow indication allowed train 891 to

proceed but required that it be prepared to stop at the next signal and restricted the

train speed to 40 mph. The clear indication allowed the train to proceed at the

maximum authorized speed.

The conductor stated that when he saw the "clear" signal, the overhead

speedometer on the

left

side of the cab, where he was seated, indicated that the

train was traveling about 29 mph

He testified that when the train was about four or five car lengths from the

signal,

he got up from his seat to get something from his bag. A moment later he

heard the engineer shout that the signal had changed The conductor said that the

"clear" aspect had changed to a red "stop" aspect and he saw the headlight of an

oncoming locomotive. He dropped to the floor and braced for the ensuing collision

The impact threw the crewmembers about within the confines of their respective

engine compartments. The engineer and the conductor sustained serious injuries,

and the brakeman was killed.

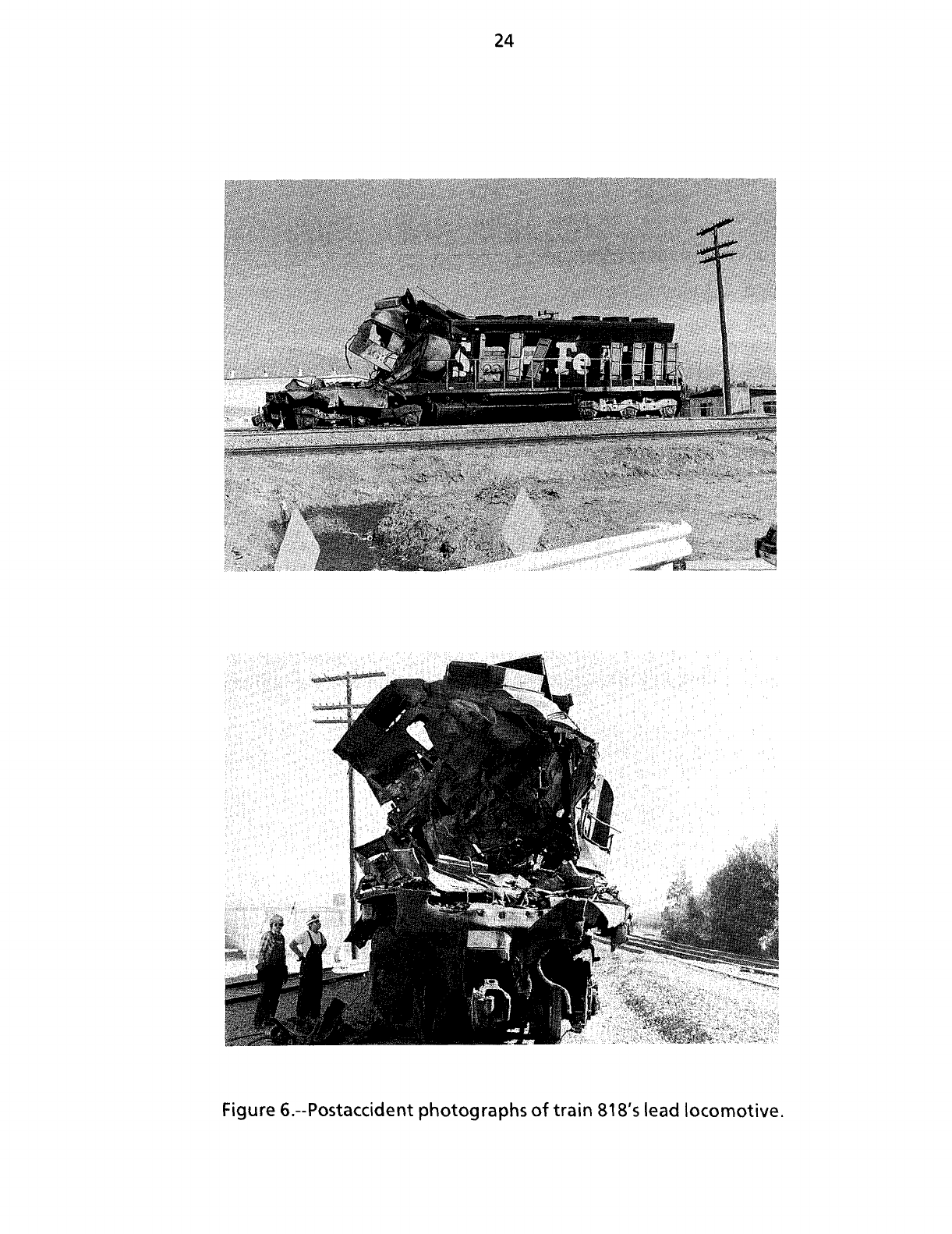

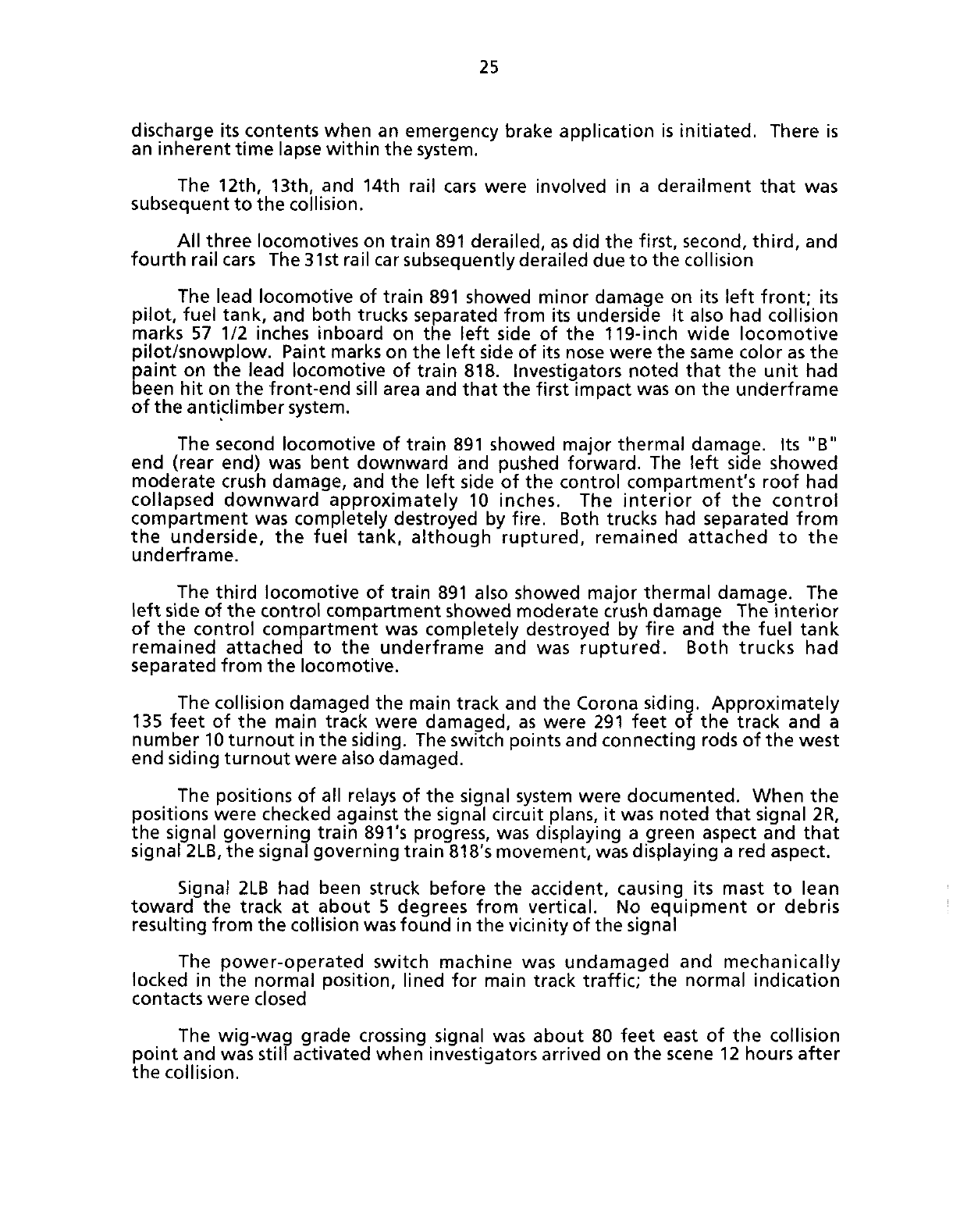

The

left

front corner end sill area of the lead locomotive unit of train 818

collided with the

left

front corner end sill area of the lead locomotive unit of

train 891; train 891's lead unit swerved to the south of the main track and landed on

its right side. The second locomotive unit landed on its

left

side along the north side

of the track The third locomotive unit proceeded eastward, ramping over parts

from the other two locomotives, and landed on top of the control cab of the lead

locomotive of train 818. An intense fire ensued.

About 4:24 a.m the

ATSF

dispatcher was notified by the Corona police

department that there was a railroad accident in the vicinity of Railroad Avenue and

Smith

Street. The dispatcher's office then notified those individuals listed on the

ATSF

emergency response form.

6An

aspect

is the

appearance

of a

fixed

signal

conveying

an

indication

5

Injuries?

Crew

of

ATSF

818 Crew of

ATSF

891 Total

Fatal

3 1 4

Serious

0 2 2

Minor 0 0 0

Total 3 3 6

Damages

The

ATSF

estimated damages

Equipment

$3,868,780

Track

50,000

Signal

35,000

Labor

10,052

Lading

Damage

450,000

Other (Railroad Property

Costs)

19,170

Total

$4,433,002

Crew Information

ATSF

818

Engineer.-On

Sunday, November 4, he worked a train from Barstow to Hobart

yard,

starting at 6:45 p m. and ending on November 5 at 7:30 a.m. He then drove

home, arriving just before 9 a.m. He went on a school field

trip

with his children,

returned home in the early afternoon, and took a short nap. After his nap, he

telephoned the

ATSF

Voice Information Processing System

(VIPS)

s

Following the

call,

he told his wife he expected to be called to work about 5 p.m. on the following

day,

November 6. He ate dinner with

his

family and went back to bed about 8 p.m.

About 1 30 a m on November 6, 1990, the wife of the engineer of train 818

received

a call from the

ATSF

crew caller^ who said her husband was to report for

work at 430 a m at Hobart yard. She woke her husband, and he

left

for Hobart

yard,

which was more than 60 miles away Before leaving, he told his wife that if he

arrived at Barstow before noon he would return home (San Bernardino) to take care

of one of their children while she attended her college

classes.

(He coowned an

automobile that was garaged in Barstow and would have used the car to travel back

to his house.) He reported at Hobart yard at 4:30 a.m and arrived in Barstow at

?The

injury

table

is

based

on

injury

criteria

used

by the

International

Civil

Aviation

Organization

(ICAO) The Safety Board uses

these

criteria

in all of its

reports.

8VIPS

is a

telephone/computer

interface

system

that

allows

ATSF

employees

to

obtain

the

current

train

line-up

and

their

own

work

status

relative

to

other

employees

in the same

pool

9The

crew

caller

gave

crewmembers

whose

home

terminal

was

Hobart

yard

as

much

as 3

hours

notice

before

they

were

to

report

for

duty

6

12:40 p m., too late to accommodate his wife He called from Barstow and told her

that since he anticipated a long layover, he did not expect to be called until the

following morning and was not going to bed until later that day

Accompanied

by the conductor and the brakeman, he checked into the

ATSF-contracted

motel at 1:30 p m. and went with them to eat. According to other

ATSF

personnel, he and the brakeman were in the recreation room of the motel

between 3:30 p.m and 6 p.m. About 6 p.m. they joined another engineer for

dinner, and they returned to the motel about 8 pm.

While

he was in Barstow, he talked to several other

ATSF

crewmembers who

were

waiting to be assigned to outbound trains Through them he became aware of

the status of the train line-up.

He

called the

ATSF

crew caller about 8:40 p.m. and learned that he was being

assigned

to a crew with a starting time of 10:15 p.m At that time he discovered that

three crews that were ahead of him in the line-up had been deadheaded.

10

During

his

conversation with the crew caller, he discussed the deadheading of the other

crews

and threatened to lay off" sick, implying that he had not slept Finally, he said

that he wanted to speak to the supervisor of train operations

(STO).

The crew caller

asked

him if he was going to accept the assignment; he replied,

"Well,

I got, I mean

what else am I going to do

...?"

During a

12-minute

recorded telephone conversation with the STO, the

engineer complained about the method of determining how trains were assigned

and,

particularly, about the deadheading of crews He told the

STO,"

.. I mean how

do you plan your life, you just live by

surprises?"

The

STO

testified that he concluded

from the conversation that the engineer had not been to bed while he was in

Barstow

He further testified that he was sympathetic to the engineer's situation At

the end of the conversation, the engineer did not lay off, he chose to accept the

assignment.

The

ATSF

regional manager testified that had the engineer asked to lay off, the

request would have been granted Although it was unusual for an employee to lay

off at an away-from-home terminal, the

ATSF

was aware that at times things

happened,

such as illness or family emergencies, that forced an employee to lay off

at an away-from-home terminal The regional manager further testified that crews

". normally would leave as a unit after they arrived as a unit"

The regional manager

said,

" . had he [the engineer] laid off, and he didn't

have

a history of it, and even though if it wasn't perceived as a good reason, I'm

confident there wouldn't have been any punitive measures taken, other than to say,

hey,

you need to get your act cleaned up . ."

10

Deadheading

is

off-duty

travel

when

train

crewmembers

are

moved

without

service but

with

pay

from

one

terminal

to

another

at the

railroad's

convenience

1

laying

off is a

method

by

which

an

employee

can

report

himself

not

available

for

duty

7

After he arrived at the Barstow terminal building, the engineer called his wife

at 10'15 p.m. to tell her that he was returning. She later told investigators that

during the telephone conversation he admitted that he was exhausted, that he had

taken only a small nap, and that he wanted to lay off. When she asked him why he

did not layoff, he replied, "I can't," and gave no further explanation

Investigators could not account for his actions between 8"55 p.m and 10 p.m.

When

the accident occurred, he had been awake for 26 hours 41 minutes, excluding

the brief period of rest in Barstow

Conductor --On November 4, the conductor was called at 9 a m. to work on a

train that was to leave Hobart at 12:01 p.m. and arrive at Barstow at 6.45 p.m. On

the following morning, November 5, he was called at 1:30 a.m. to take a return train

to Hobart that

left

at 2.45 a.m. and arrived at

10:15a.m.

He went home, and at

approximately 1:30 a.m. on November 6, he received his next

call,

which was again

to work a tr,ain from Hobart yard to Barstow.

As

had the engineer, the conductor reported at Hobart yard for a

trip

that

started at 4:30 a.m. on Tuesday, November 6 At 12:40 p m., he arrived at Barstow

yard.

He called his wife and told her that he would probably not get a return train

until about 5 a.m. the following day and that he was going to bed.

After eating with his crew, he returned to the motel and went to his room.

Investigators could not account for his actions between 230 p m. and 8 45 p.m ,

when the crew caller told him that he was assigned to train 818 The conversation

between him and the crew caller was recorded; the conductor sounded as if he had

just been awakened. When the accident occurred, he had been awake for

approximately 6 hours.

Brakeman-At 1:30 a.m. on November 6, the crew caller told the brakeman

that she was to go on duty at 4 30 a m. at Hobart yard. The

trip

was her first

interterminal tour as a brakeman. She

left

her house at 2.30 a.m and arrived at

Hobart yard about 3am

At Barstow, she joined the crew for a meal. When the crew returned to the

motel, she remained in the engineer's company until shortly after 8 p.m , when she

went to her room. The

ATSF

crew caller reached her at 8.43 p.m. and assigned her to

train 818. Her conversation with the crew caller was taped, and she sounded as if she

had just been awakened.

She

was next seen at

San

Bernardino yard, where the train

stopped for a 4-minute layover and she dismounted the engine. When the accident

occurred,

she had been awake for 26 hours 41 minutes, excluding the brief period of

rest in Barstow. Her activities on November 6 between 8 p.m and 10 p m. were

unknown

ATSF891

Engineer.-On Tuesday, November 6, at 11.15 p.m , the

ATSF

crew caller

reached the engineer and assigned him to train 891, which was to originate in

Hobart yard at 2 a.m. on Wednesday, November 7, and go to Barstow. He arrived at

Hobart yard about 1:30 a.m. and

left

about 3.10 a m. He had been off duty 25 hours

45 minutes before reporting to Hobart yard. He had been awake for 4 hours 56

minutes at the time of the collision and stated (during a postaccident interview with

investigators) that he had slept for most of the day and evening on Tuesday until he

was

awakened by the crew caller.

8

Conductor --On November 6, the conductor received a call from the

ATSF

crew

caller at 11' 15 p m , assigning him to train 891 En route to Hobart yard, he picked

up his brakeman for train 891; the two reported to Hobart yard about 2 a.m and

left

about 3:10 a.m. The conductor testified that he was in the controlling compartment

of the lead locomotive He had been off duty for 28 hours 20 minutes before

reporting to work. At the time of the accident, he had been awake for 6 hours

11 minutes

Brakeman

-He received his call assigning him to train 891 about 11:15 p.m. on

November 6. According to the conductor, the brakeman boarded the second

locomotive of his own volition. Before boarding the train, he had been off duty for

28 hours 20 minutes He had been awake 5 hours 11 minutes at the time of the

accident

Train Information

General -The

ATSF

assistant chief mechanical officer testified that

ATSF

locomotives had been equipped with alertersiz until about 10 years earlier. Due to

mechanical difficulties and lost production time, the

ATSF

had removed them. The

ATSF

did not use cab

signals^

in locomotives.

The assistant chief mechanical officer stated that the

ATSF

had a policy of

installing event recorders on even-numbered locomotives Investigators found that

in the fleet of about 1,800 locomotives, 65 odd-numbered units also were equipped

with event recorders. The officer said that the

ATSF

attempted to have an event

recorder on "97 percent" of its engine

consists

that were in road

service.

ATSF

818.-Train

818 consisted of 5 locomotives and 91 rail

cars

The

locomotive consist included

ATSF

5363

(Electro Motor Division

EMD-SD

45),

ATSF

5267

(EMD-SD

40-2),

ATSF

5395

(EMD-SD

45),

ATSF

8063

(General Electric-C

30-7),

and

ATSF

5328

(EMD-SD

45). Of the five locomotives units, only the

fifth

had an

event recorder.

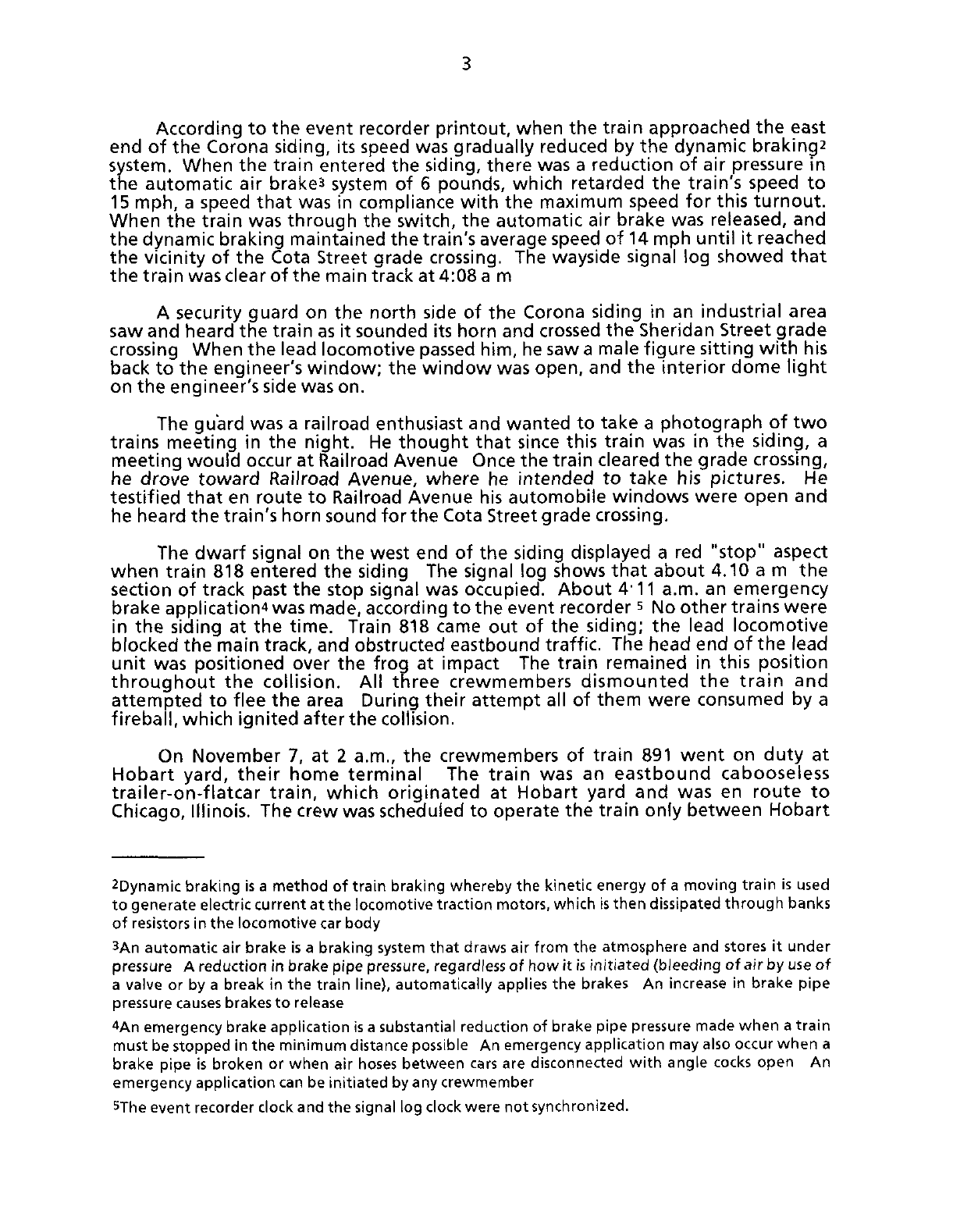

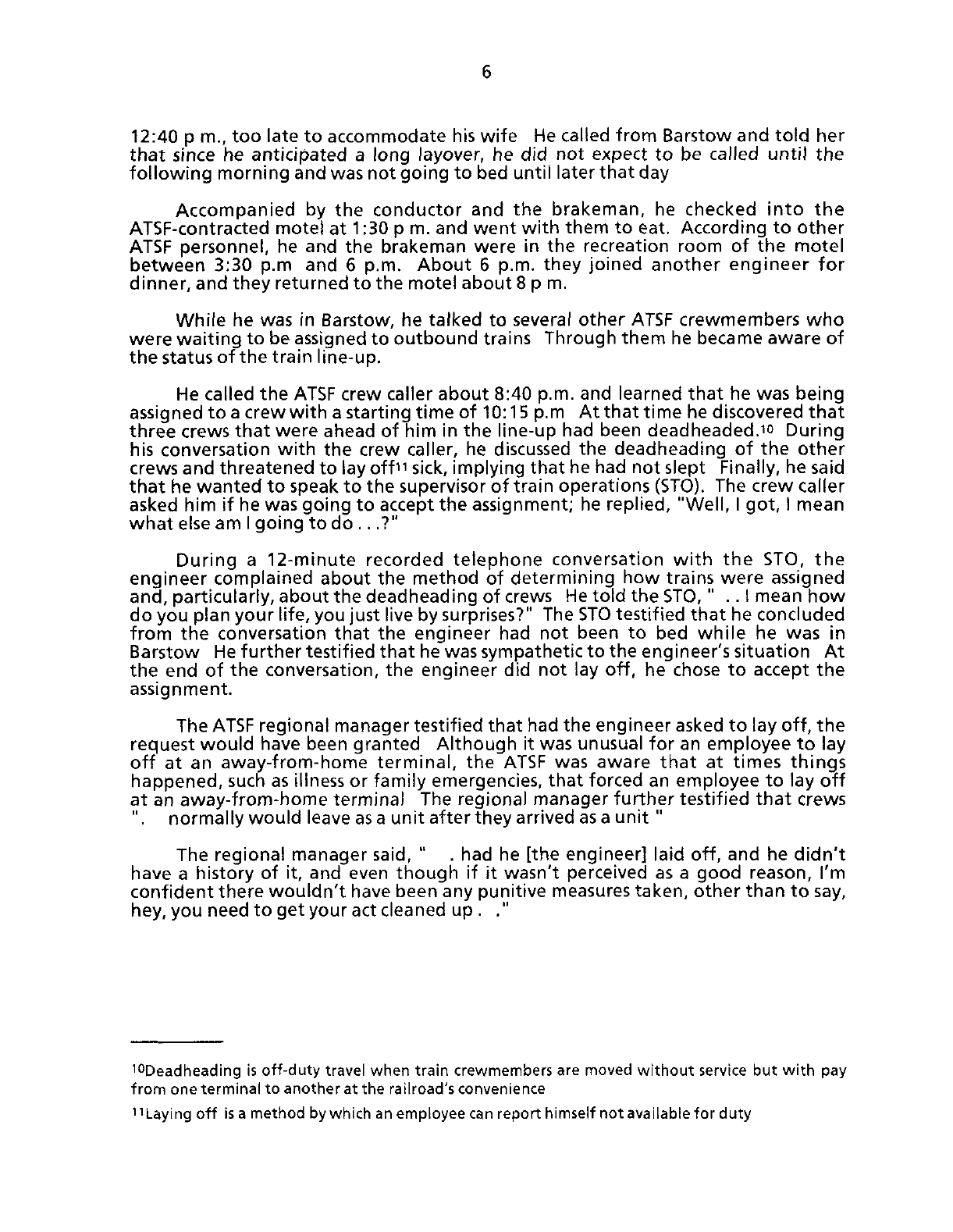

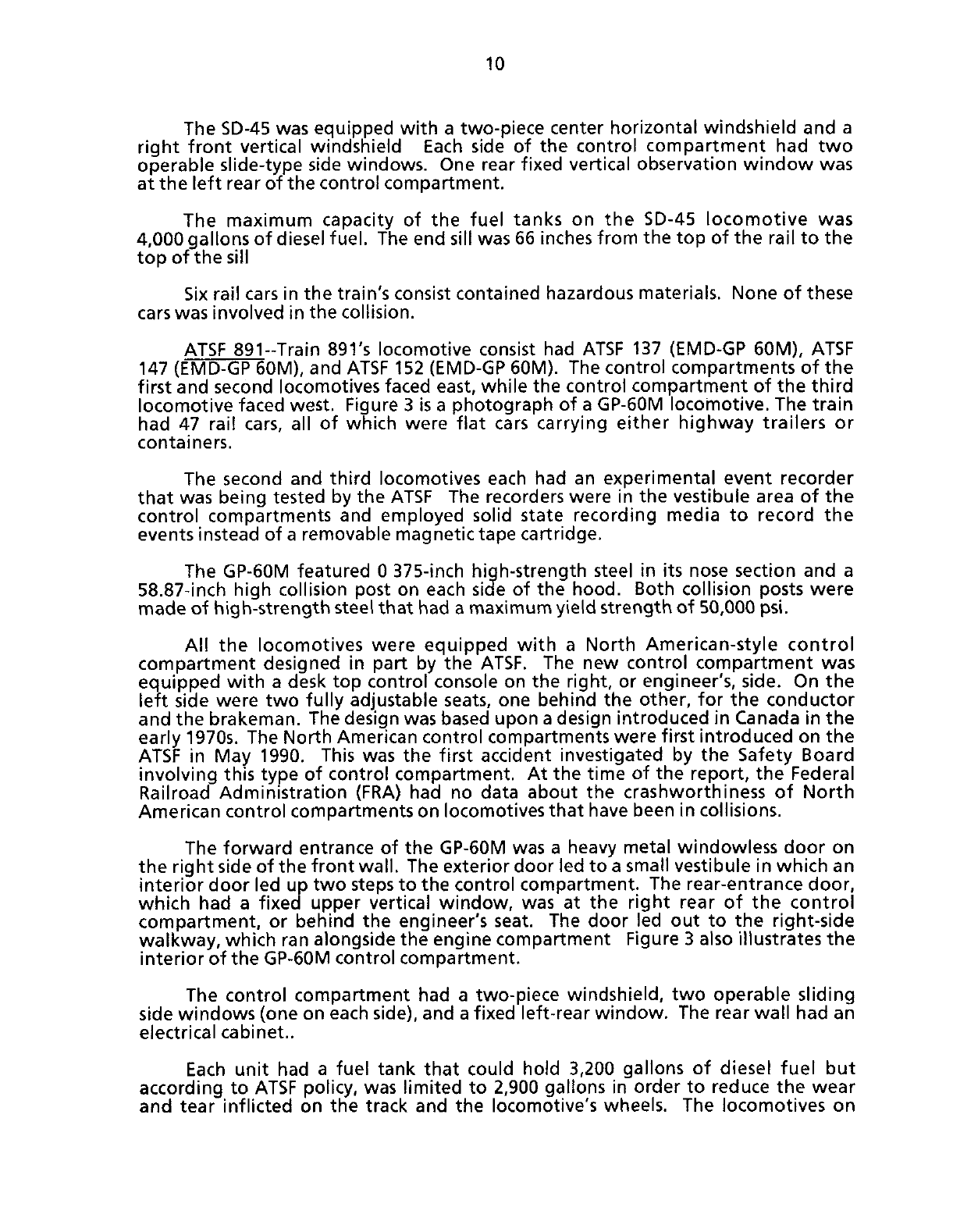

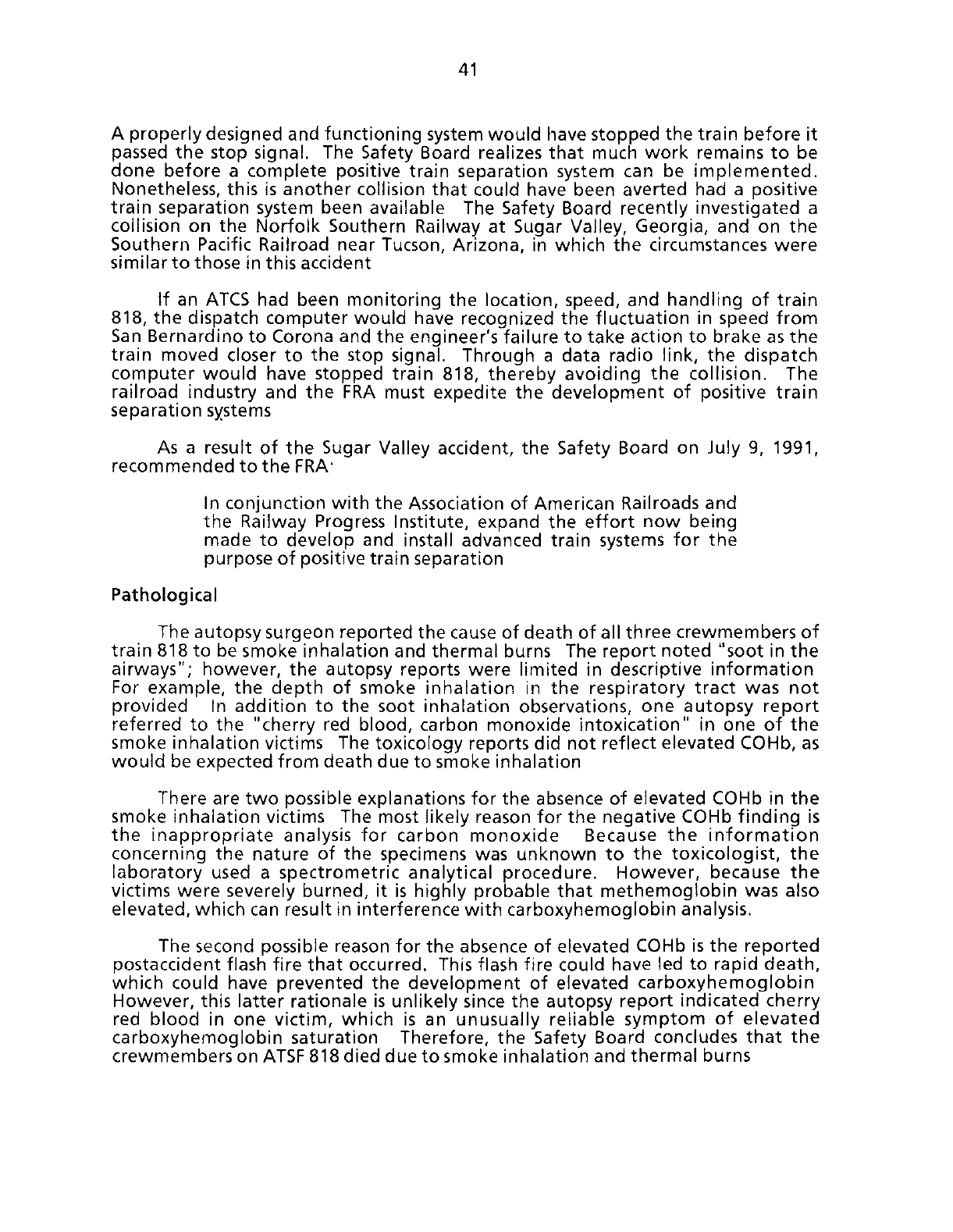

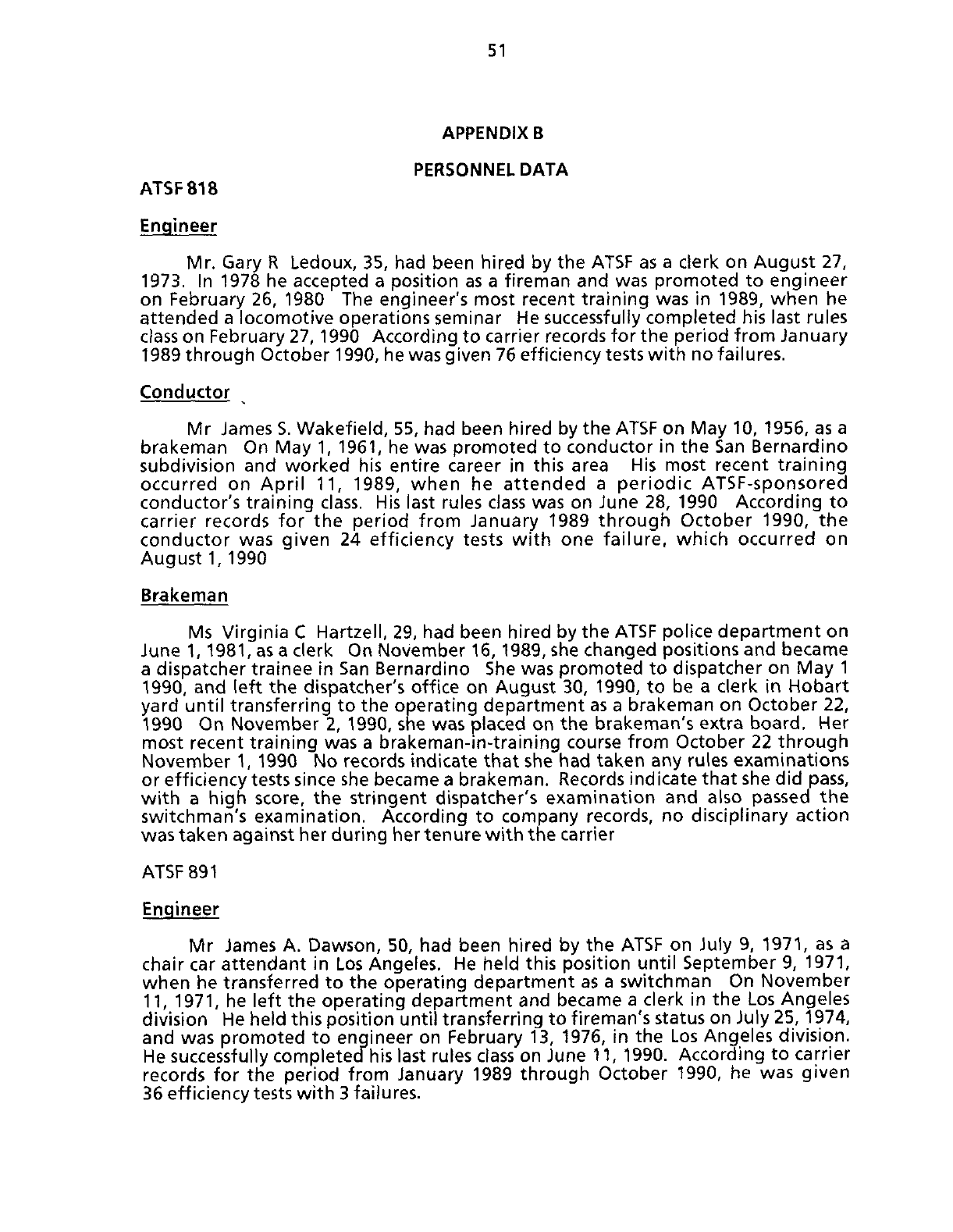

The SD 45 locomotive had 11-gauge (or 0 125) mild steel in its nose section The

collision posts on the SD-45 were 59 inches high on the

left

and 54 inches high on the

right.

Both

posts were made of mild steel with a specified minimum yield strength

of

27,000

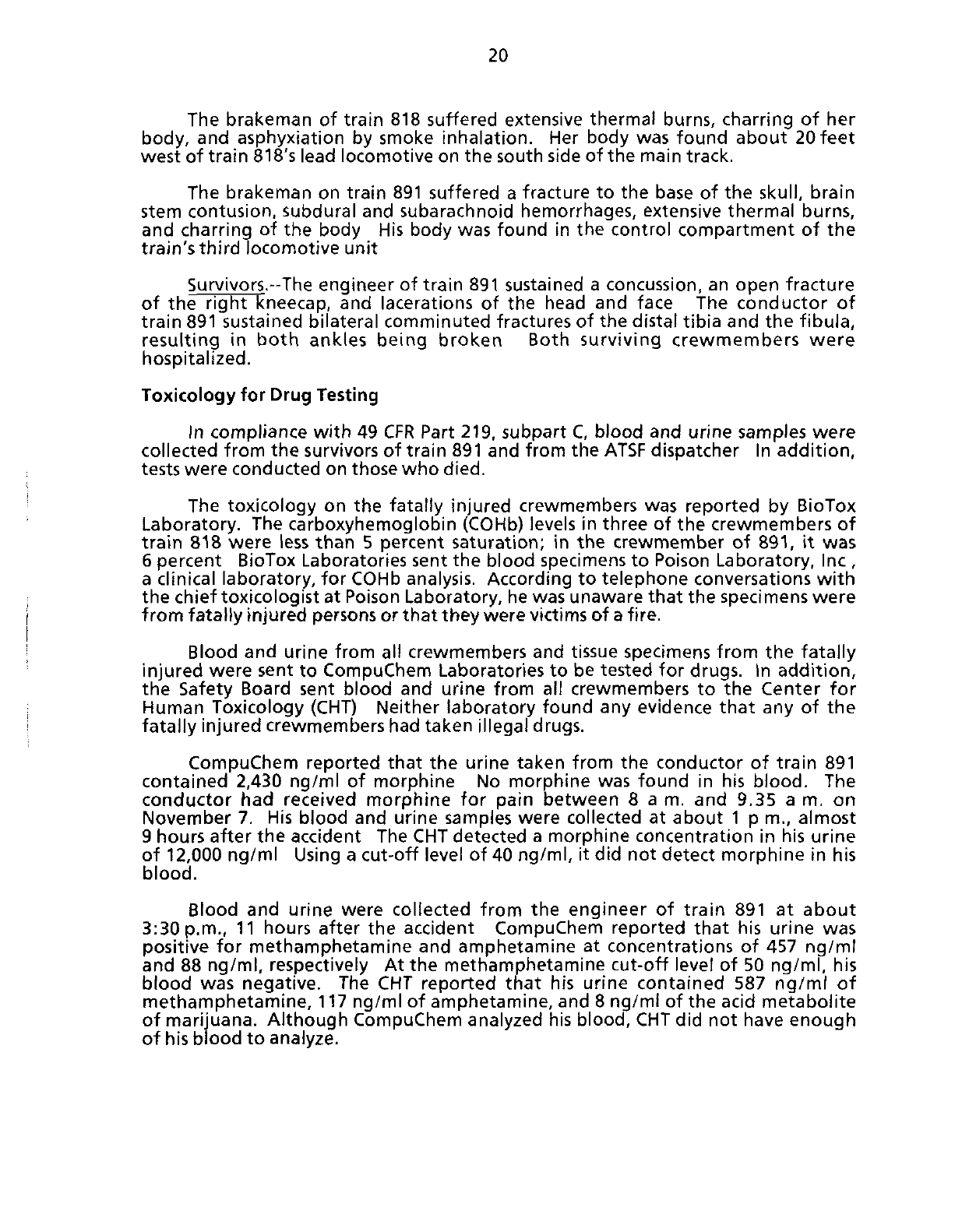

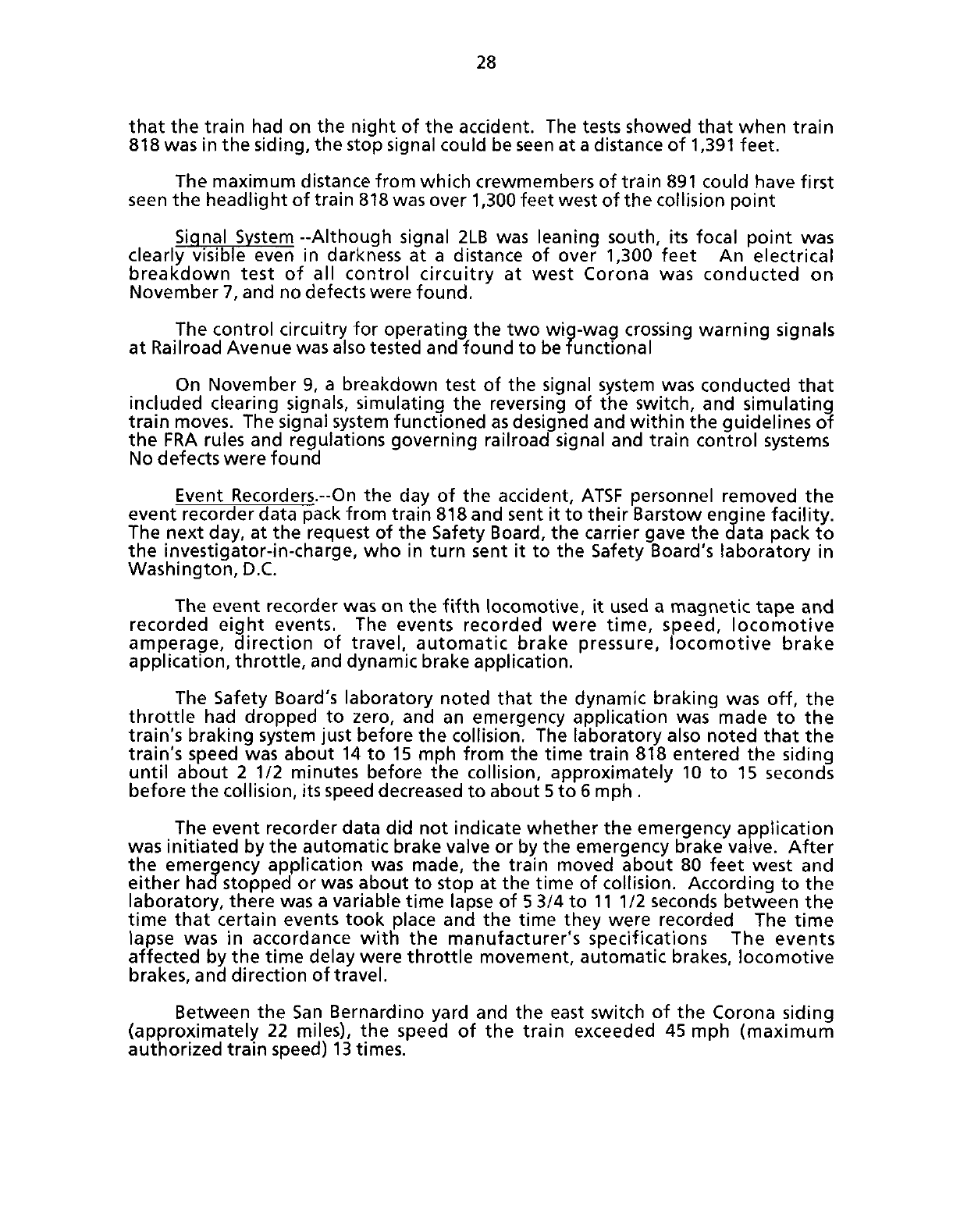

pounds per square inch (psi) See figure 2 for a photograph of an SD-45

locomotive.

The control compartment of the SD-45 was a standard design that had been

used

in the railroad industry since the early

1960s

The control compartment was

configured with the engineer's position on the right side and with the control stand

on the engineer's left. Two fully adjustable seats were on the

left

side wall, one

forward and one aft, forthe conductor and brakeman

i2An

alerter

is a

device

that

monitors

the

engineer

for

activity

and

provides

a

visible

and

audible

warning

for a

predetermined

length

of

time

after

which

a

penalty

air

brake

application

is

made

if the

system

is not

reset

13A

cab

signal

is a

device

in the

control

cab of the

locomotive

that

indicates

the

condition

of the

track

ahead

(clear

or

occupied)

by

displaying

lighted

signals

9

Figure

2.--SD-45

locomotive.

Top: General Motors Electro-Motive Division.

Bottom:

Engineer's control stand.

10

The SD-45 was equipped with

a

two-piece center horizontal windshield

and a

right

front

vertical windshield

Each

side

of the

control compartment

had two

operable slide-type side windows. One rear

fixed

vertical observation window was

at the

left

rear

of

the control compartment.

The

maximum

capacity

of the

fuel tanks

on the

SD-45 locomotive

was

4,000

gallons

of

diesel fuel. The end sill was

66

inches from the

top of

the rail

to the

top

of

the sill

Six

rail

cars

in the

train's consist contained hazardous materials. None

of

these

cars

was involved in the collision.

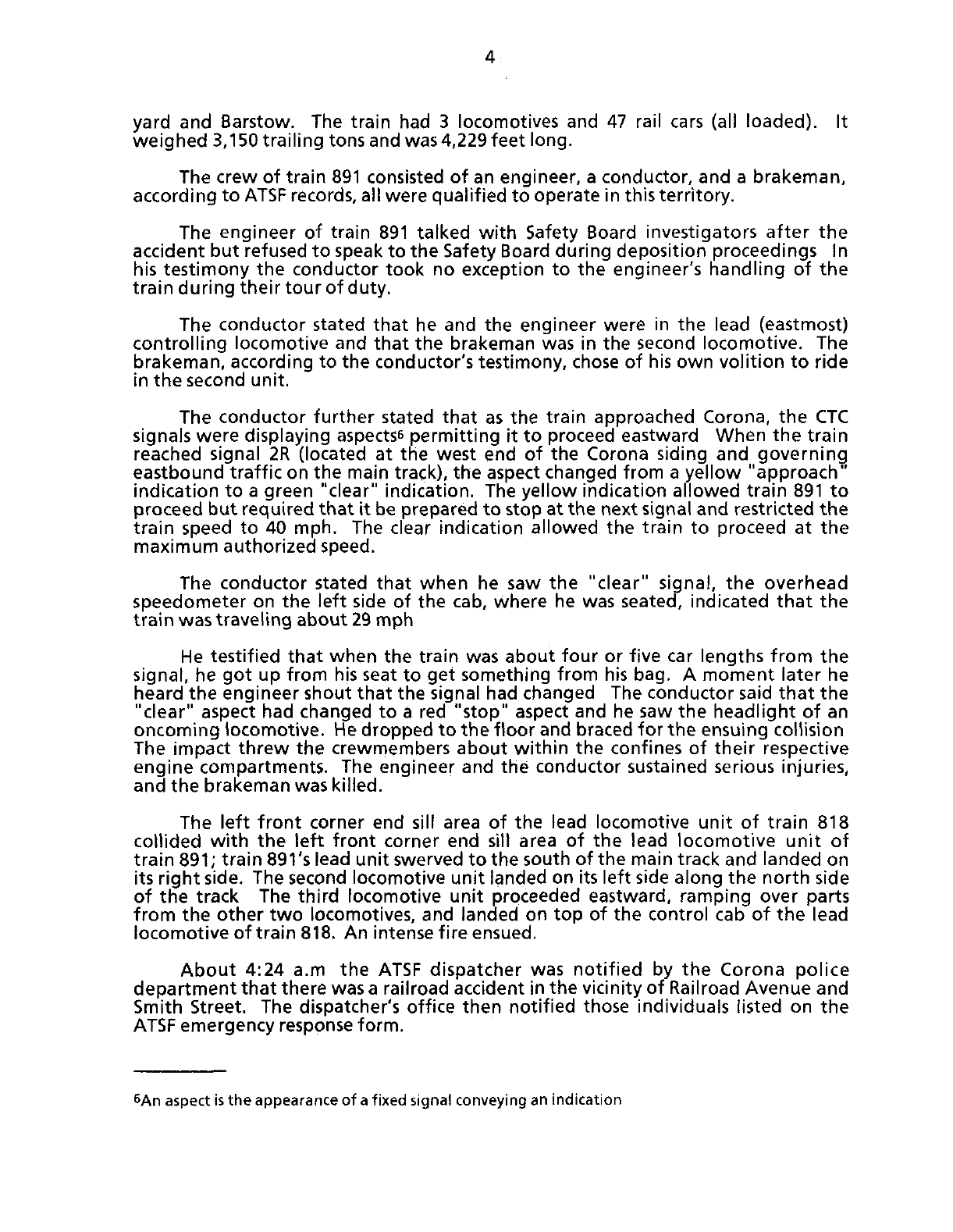

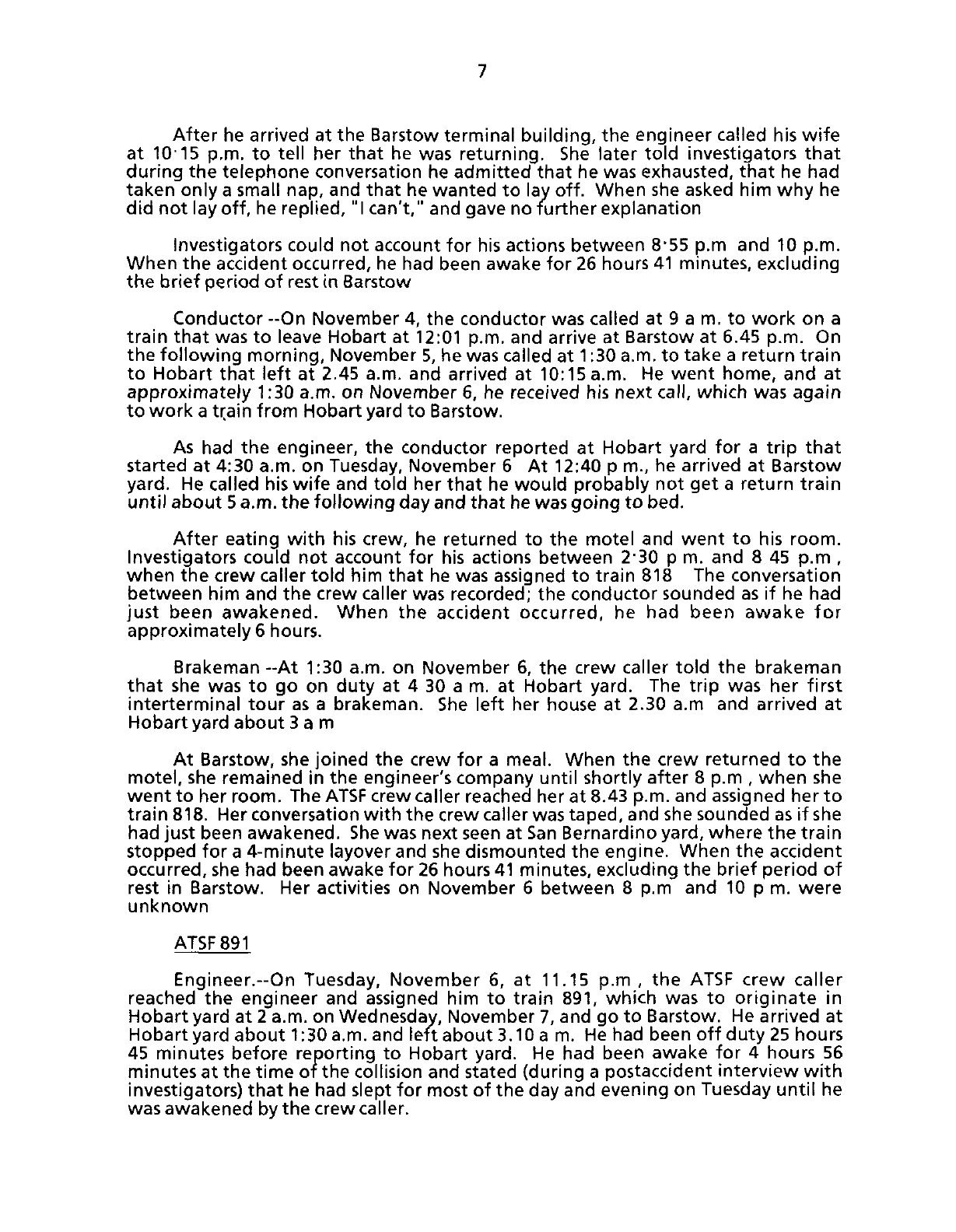

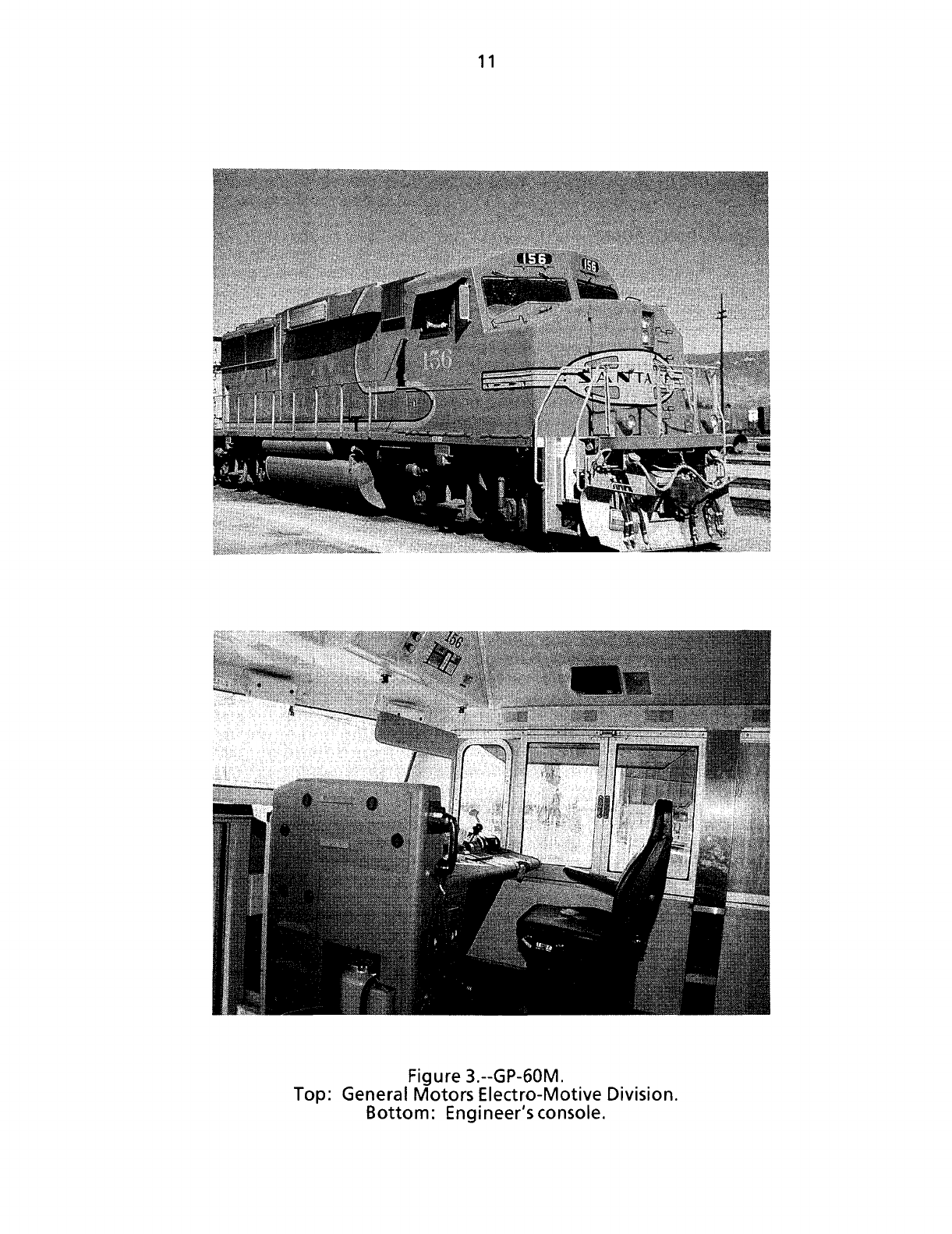

ATSF

891-Train

891's

locomotive consist

had

ATSF

137

(EMD-GP

60M),

ATSF

147

(EMD-GP

60M), and

ATSF

152

(EMD-GP

60M). The control compartments

of the

first and second locomotives faced east, while

the

control compartment

of the

third

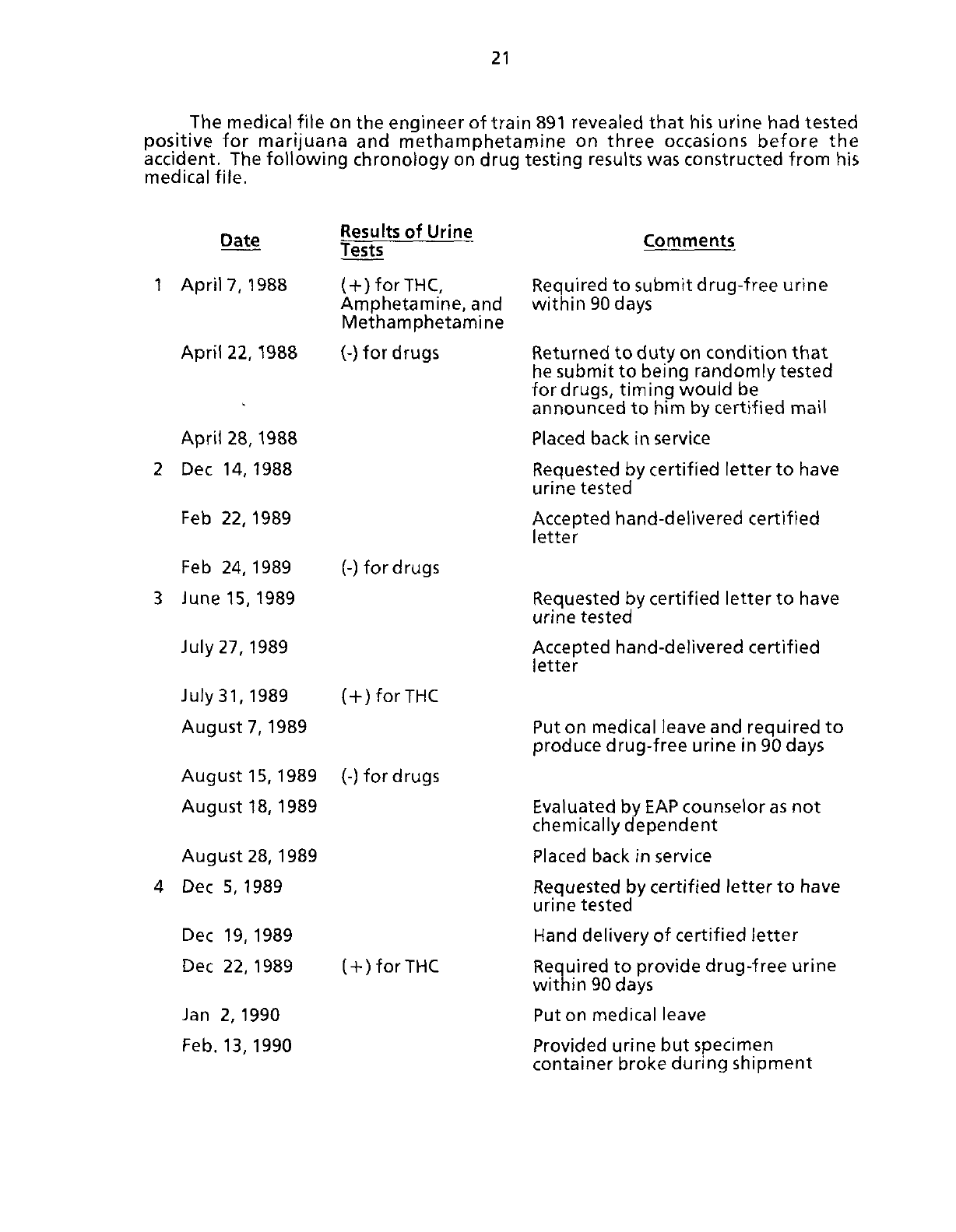

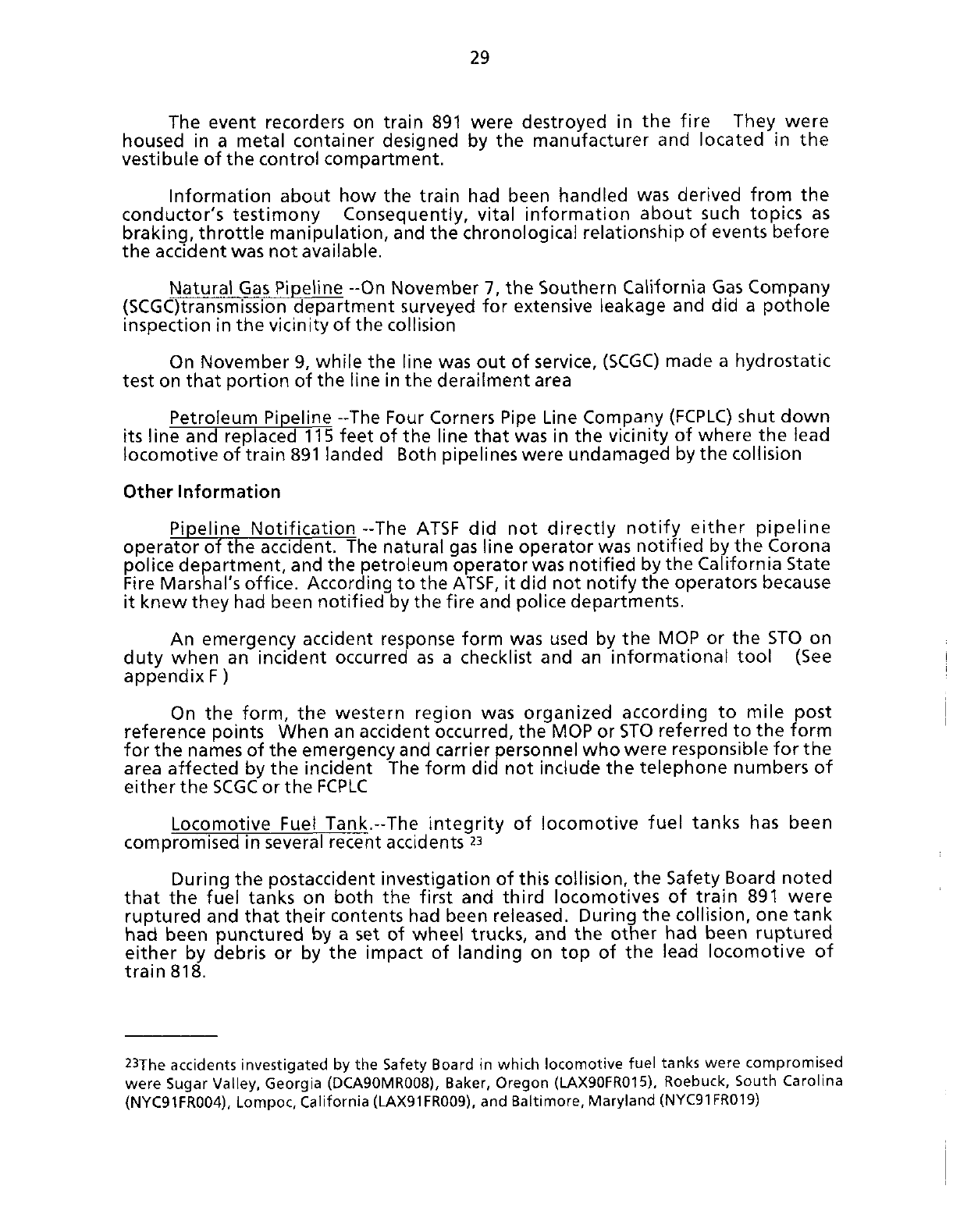

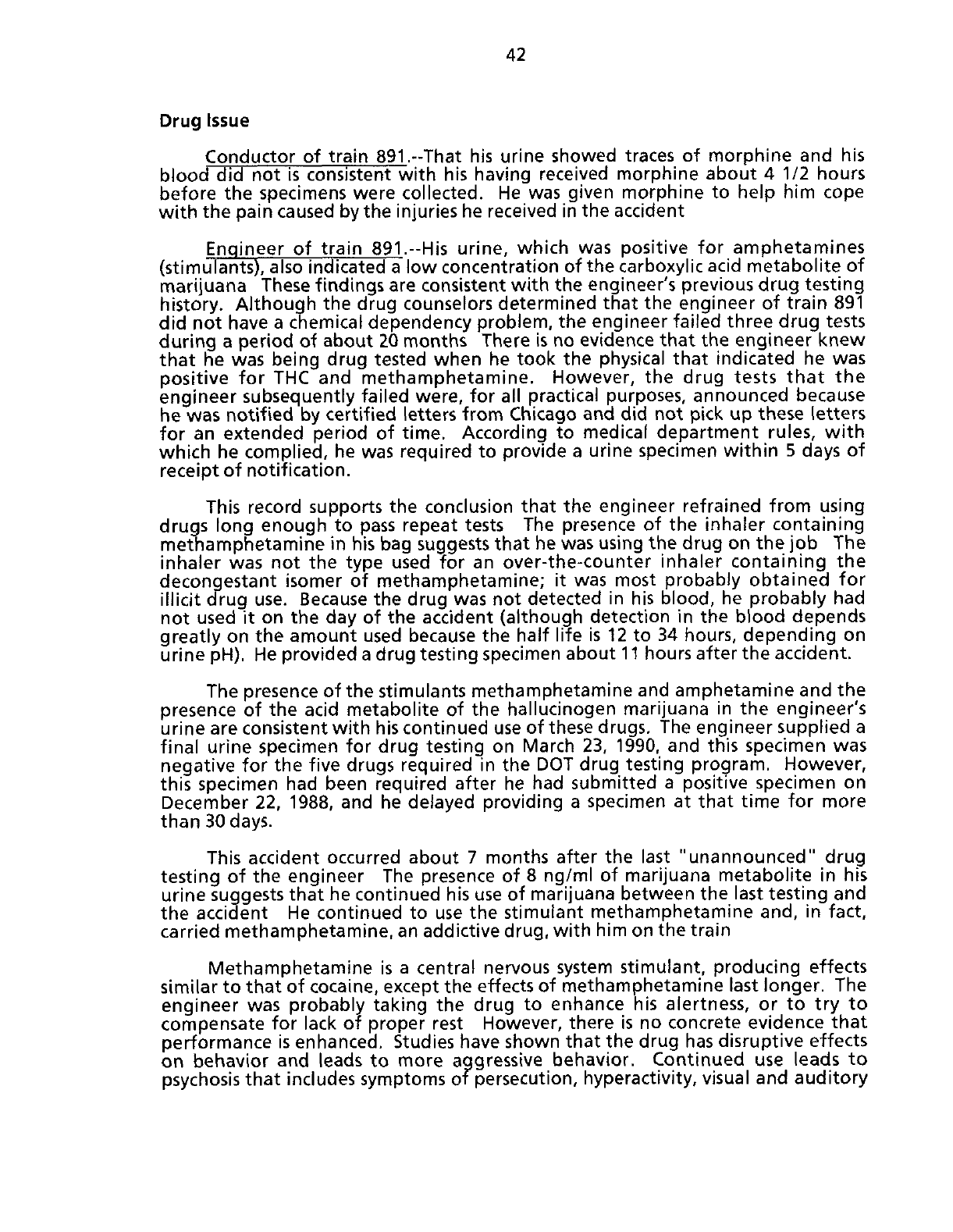

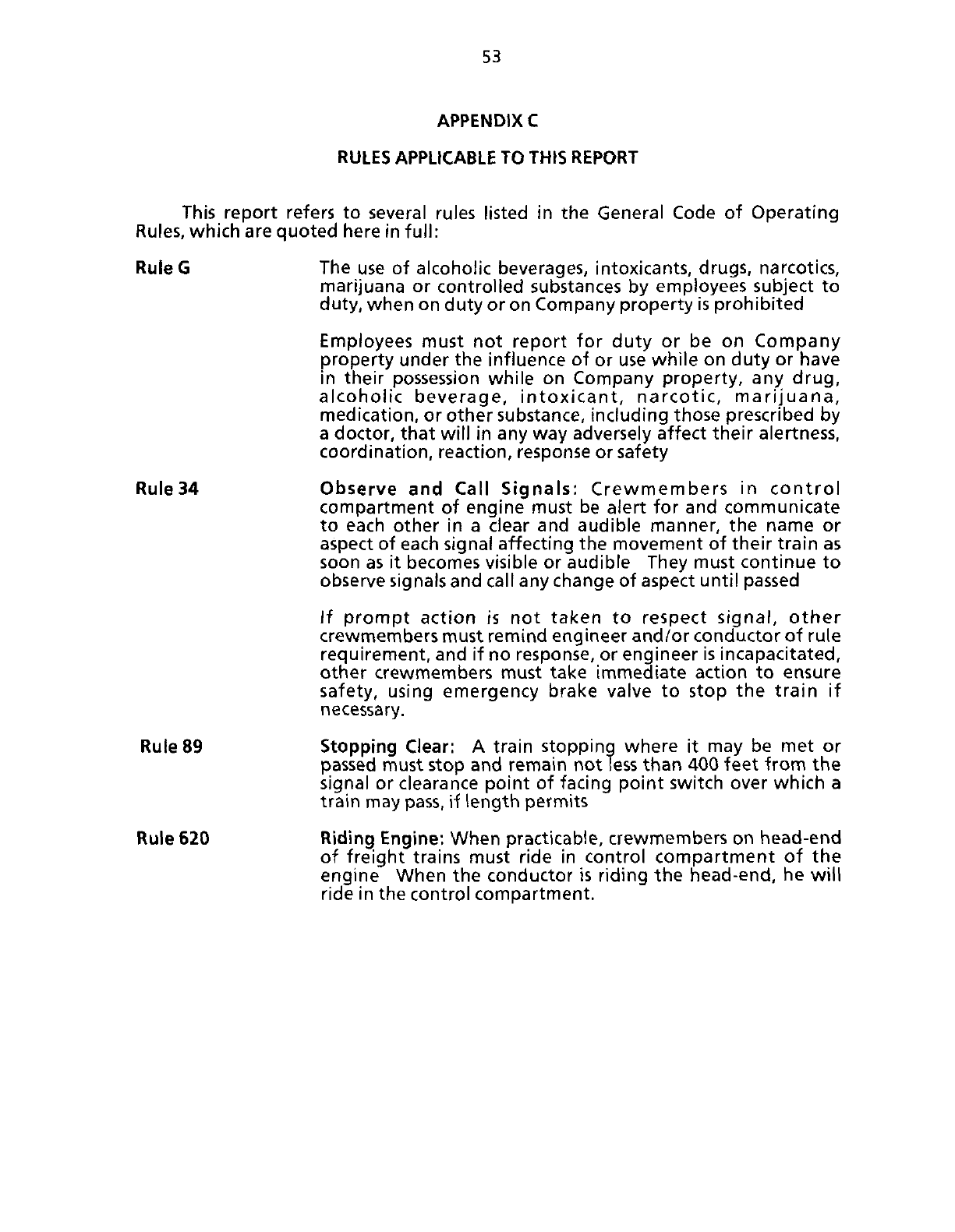

locomotive faced west. Figure

3

is

a

photograph

of a

GP-60M locomotive. The train

had

47

rail

cars,

all of

which were

flat

cars

carrying either highway trailers

or

containers.

The second

and

third locomotives each

had an

experimental event recorder

that

was being tested

by the

ATSF

The

recorders were

in the

vestibule area

of the

control compartments

and

employed solid state recording media

to

record

the

events

instead

of

a removable magnetic tape cartridge.

The GP-60M featured

0

375-inch

high-strength steel

in its

nose section

and a

58.87-inch

high collision post

on

each side

of the

hood.

Both

collision posts were

made

of

high-strength steel

that

had

a

maximum

yield strength

of 50,000

psi.

All

the

locomotives were equipped with

a

North American-style control

compartment designed

in

part

by the

ATSF.

The new

control compartment

was

equipped with

a

desk

top

control console

on the

right,

or

engineer's, side.

On the

left

side were

two

fully adjustable

seats,

one

behind

the

other,

for the

conductor

and the brakeman. The design was based upon a design introduced

in

Canada in

the

early

1970s.

The North American control compartments were first introduced on

the

ATSF

in May 1990.

This was

the

first accident investigated

by the

Safety

Board

involving this type

of

control compartment.

At the

time

of the

report,

the

Federal

Railroad

Administration (FRA)

had no

data about

the

crashworthiness

of

North

American control compartments on locomotives

that

have been in collisions.

The forward entrance

of the

GP-60M was

a

heavy metal windowless door

on

the right side

of

the

front

wall. The exterior door led

to a

small vestibule in which

an

interior door led up two steps

to

the control compartment. The rear-entrance door,

which

had a

fixed

upper vertical window,

was at the

right rear

of the

control

compartment,

or

behind

the

engineer's seat.

The

door

led out to the

right-side

walkway, which ran alongside the engine compartment Figure

3

also illustrates

the

interior

of

the GP-60M control compartment.

The control compartment

had a

two-piece windshield,

two

operable sliding

side

windows (one on each side), and a

fixed

left-rear window. The rear wall had

an

electrical cabinet..

Each

unit

had a

fuel tank

that

could hold

3,200

gallons

of

diesel fuel

but

according

to

ATSF

policy, was limited

to 2,900

gallons

in

order

to

reduce

the

wear

and tear inflicted

on the

track

and the

locomotive's wheels.

The

locomotives

on

11

Figure 3.--GP-60M.

Top: General Motors Electro-Motive Division.

Bottom: Engineer's console.

12

train 891 had fast been fueled in

Belen,

New Mexico, on November 5; they

left

Hobart yard with approximately 1,000 gallons

each.

The sill height of the GP-60M was 63 inches from the top of the rail to the top

of the

sill.

Track and Signal Information

Track --At the collision point there was a single main track and a parallel siding,

both extending east to west The collision point was directly west of the Railroad

Avenue

grade crossing in the vicinity of the turnout

that

connected the single main

track and the west end of the Corona siding

(See

figure 1.) The accident occurred in

a light industrial area of warehouses and small shops Working street lamps flanked

and lit the north and south sides of the grade crossing

The track entering the Corona siding from the east had a descending gradient

of 0.47 percent for 1,306 feet. The track gradient continued to descend at

0.82 percent for 1,400 feet, at which point it became level. It was level for

2,685

feet

and then ascended at a gradient of 0 44 percent for

2,250

feet At

that

point, the

track gradient ascended 0.08 percent for 866 feet until it reached the west siding

turnout near Railroad Avenue

The main track extended east to west. The alignment at the collision point was

tangent. The main track was tangent for 8,184 feet from signal 272 to signal 2R and

continued to be tangent for another 40 feet past signal 2Rto the collision point. The

gradient at the collision point was descending at 0 08 percent

According

to the

ATSF

assistant superintendent of maintenance, the main track

was

maintained to

class

4 track standards^ at the Railroad Avenue grade crossing

The last time the track was inspected before the accident was on November 5 by an

ATSF

track inspector, and no defects were noted or reported

Siqnal.-The

signal system consisted of a traffic control system for a single-track

railroad having Union Switch and Signal Company

(US&S)

H-5 searchlight-type

signals

and a

US&S

M22A

dual-control switch machine. Noncoded track and line

circuits

were controlled from a

US&S

computer-aided dispatching center in San

Bernardino

The 2LB dwarf signal at the west end of the siding governed westbound traffic;

it was located near Railroad Avenue and displayed a "stop" indication when

train 818 entered the siding. According to the signal log, at 11 seconds past

4 10 a.m , the track circuit on the siding west of the

2LB

signal was occupied

Signal

2R, which was west of the west end of the Corona siding and along the

south side of the main track, was a home signal governing eastbound traffic.

According

to the signal log, at 8

seconds

past 4.09 a m , it displayed a "clear" aspect;

and at 11 seconds past 4-10 a m , it showed a red "stop" aspect, signifying

that

the

track circuit east of the signal was occupied

14

According

to 49 CFR

213.9,

class 4

track

is a

segment

of

track

maintained

to

accommodate

the

maximum

allowable

speed

of 80 mph for

passenger

trains

and the

maximum

allowable

speed

of 60

mph for

freighttrains

13

The Railroad Avenue grade

crossing

was protected by wig-wag warning signals

on

a mast alongside the roadway A round disc with a red lens lamp in its center

hung from the mast. When the crossing warning signal was activated, a bell rang

and the

disc

swung from side to side.

Radio

-The existence of recorded conversations between the dispatcher and

both crews shows

that

each train had an operational radio on board its respective

control locomotive. The

ATSF's

single radio frequency was used for "point to train"

communication, or communication by locomotive radio between the traincrew and

the dispatcher. The frequency was also used for "end to end" communication, or

communication by hand-held portable radio between the conductor and the rest of

the traincrew The dispatchers were in

San

Bernardino.

Operational

Information

Work/Rest

Cycles.-ATSF

operating employees used their seniority to place

themselves

in available work positions. The positions were in freight pool

service,

in

yard

service,

on routinely operated local trains, or on an

extra

board.is Employees

assigned

to yard and local train service had schedules

that

were generally based on

preestablished starting times.

The Safety

Board

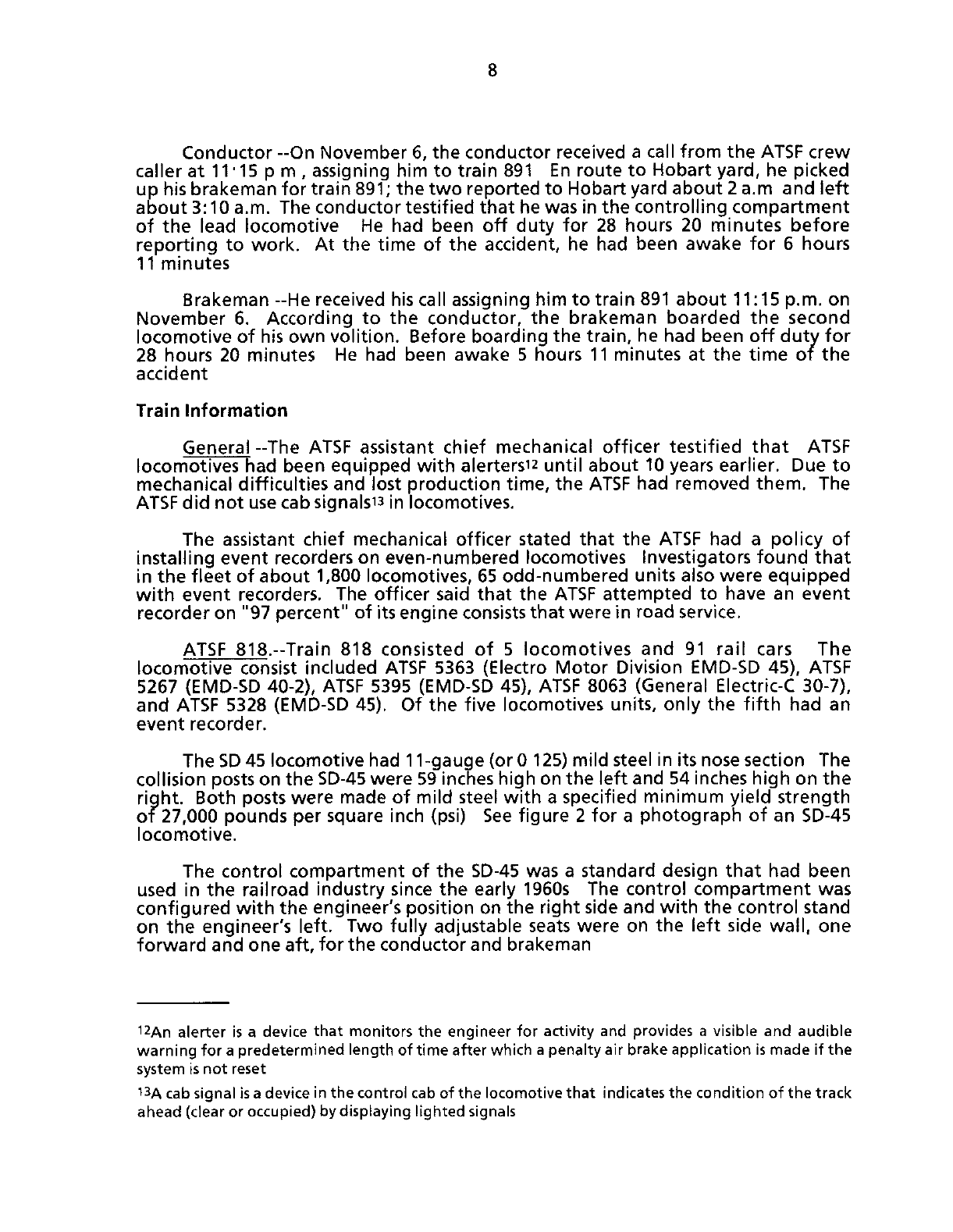

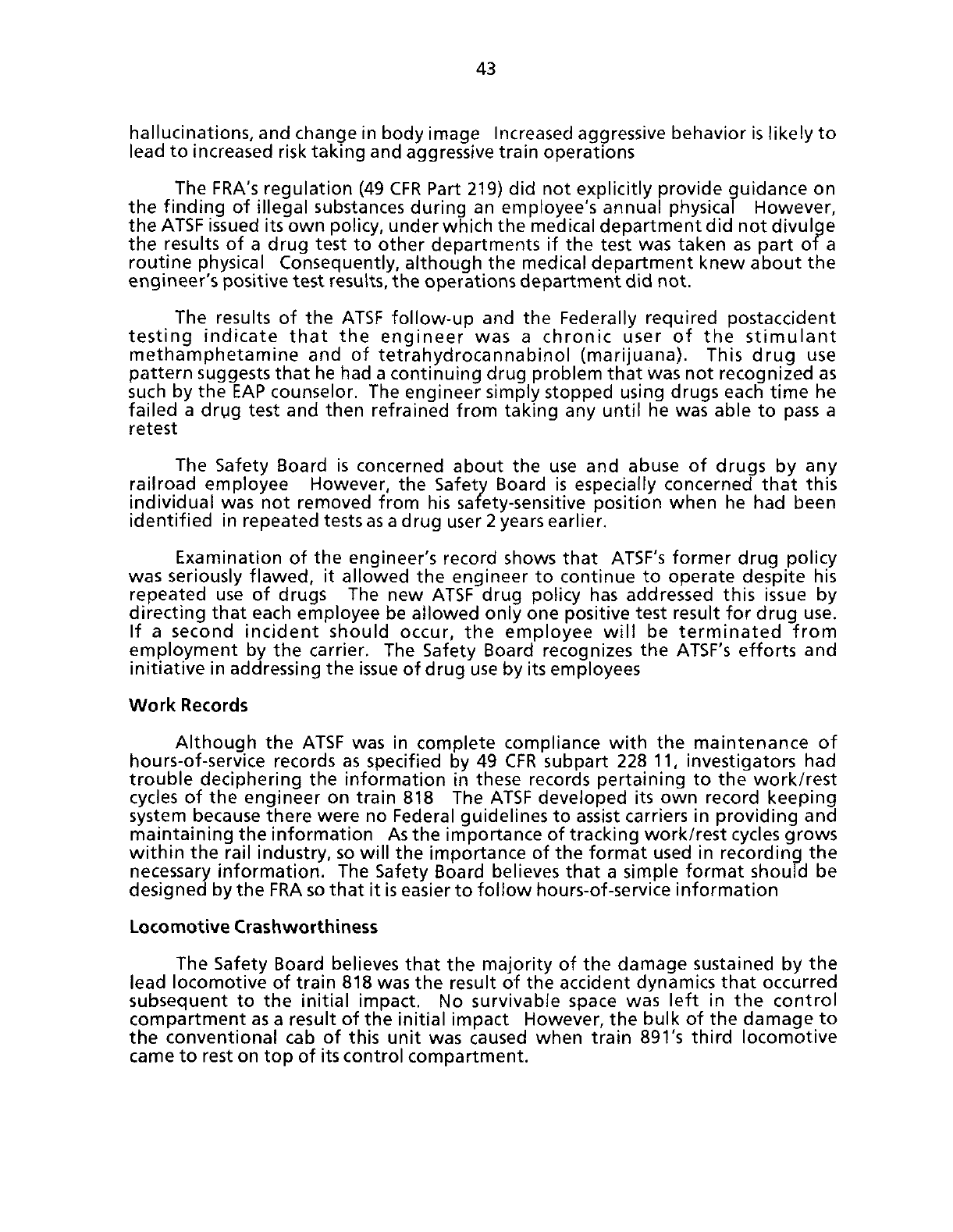

obtained a list of the duty times for the engineer of train 818

during the

90-day

period (August 8 to November 6) before the accident. On

August

8,9, and 10, he worked in pool

service.

On August 11, he laid off on personal

leave

before beginning a vacation

that

lasted 22

days,

from August 12 until

September 2.

He

notified the carrier

that

he was available for service at 12'01 a m on

September 3 He got his first train on September 5 and remained in pool service

through September 16. On September 17, he transferred to the

extra

board and

remained on it through October 7, when he transferred back to pool

service.

From

October 7 until November 6, he worked nearly every time the pool rotation made

work available.

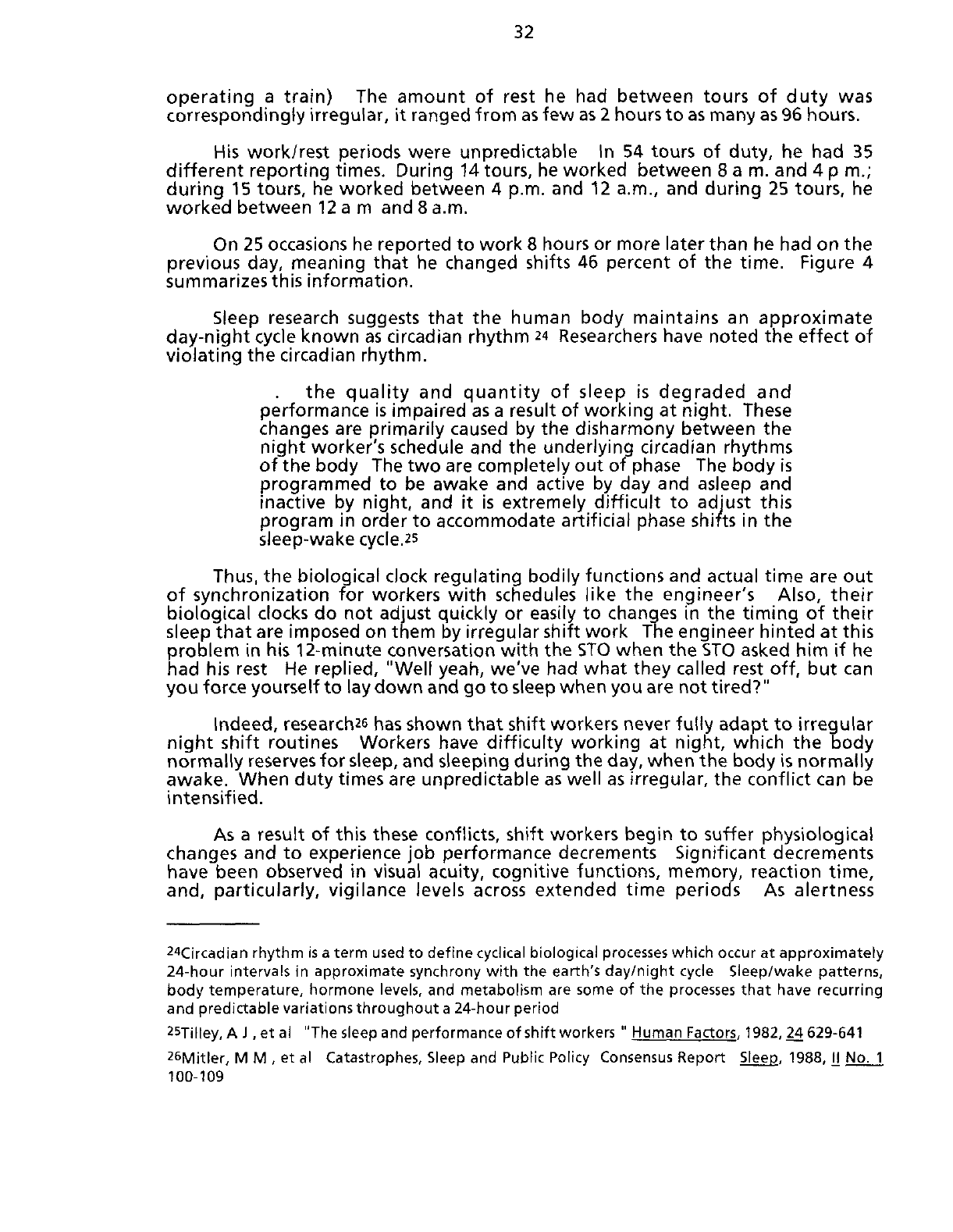

In the 64 days from September 5 through November 7, he worked 47 calendar

days

His tours included 3 in yard service and 53 in road

service;^

of the 56 tours, 7

were

deadheaded. On seven

occasions,

he had two tours of duty

that

started on the

same

calendar day.

(See

figure 4)

He

laid off

1

day on personal leave, 2 days

sick,

and 2 days while on

calM?

at his

home terminal. The carrier did not discipline him either time for marking off while

on

call.

Investigators noted

that

his average time on duty when he operated a train

was

7 hours 18 minutes. His average deadhead time was 2 hours 41 minutes. His

off-duty time between trips at his home terminal ranged from 11 hours 45 minutes

to 96 hours, the average time was 33 hours 12 minutes. His off-duty time at his

away-from-home terminal ranged from 2 to 27 hours; the average was 11 hours

15

Extra

board

engineers

fill

in

temporary

vacancies

created

when

other

employees

lay off for any

reason

These

vacancies

occur

in

freight

pools,

yard

service,

and

local

trains

15

Road

service

is the

movement

of

freight

over

the

railroad

from

one

terminal

to

another.

!7An

employee

is

considered

to be on

call

24

hours

a day If he

lays

off--says

he

cannot

work-without

giving

the

carrier

8

hours

notice,

he is

said

to be

"laying

off on

call

"

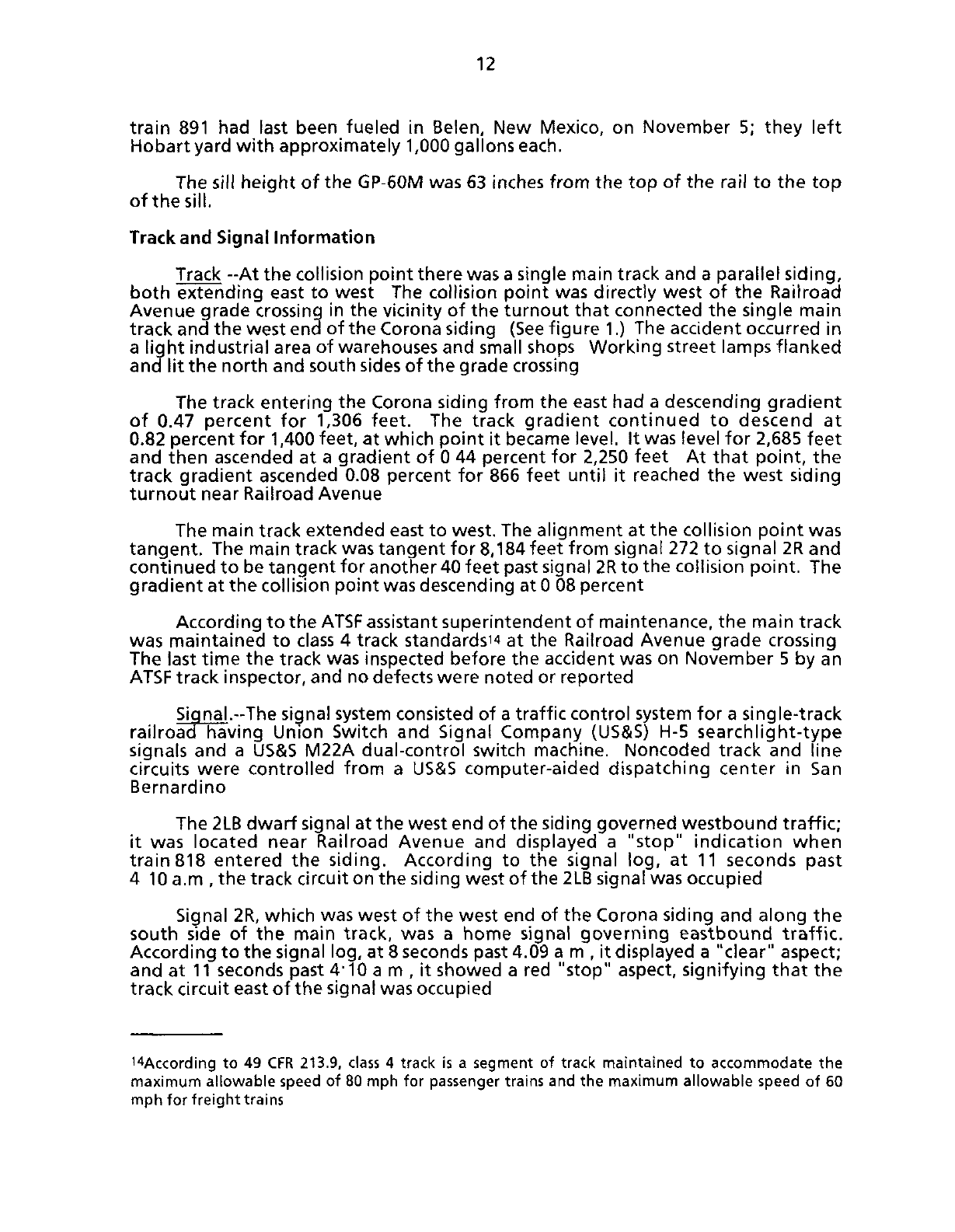

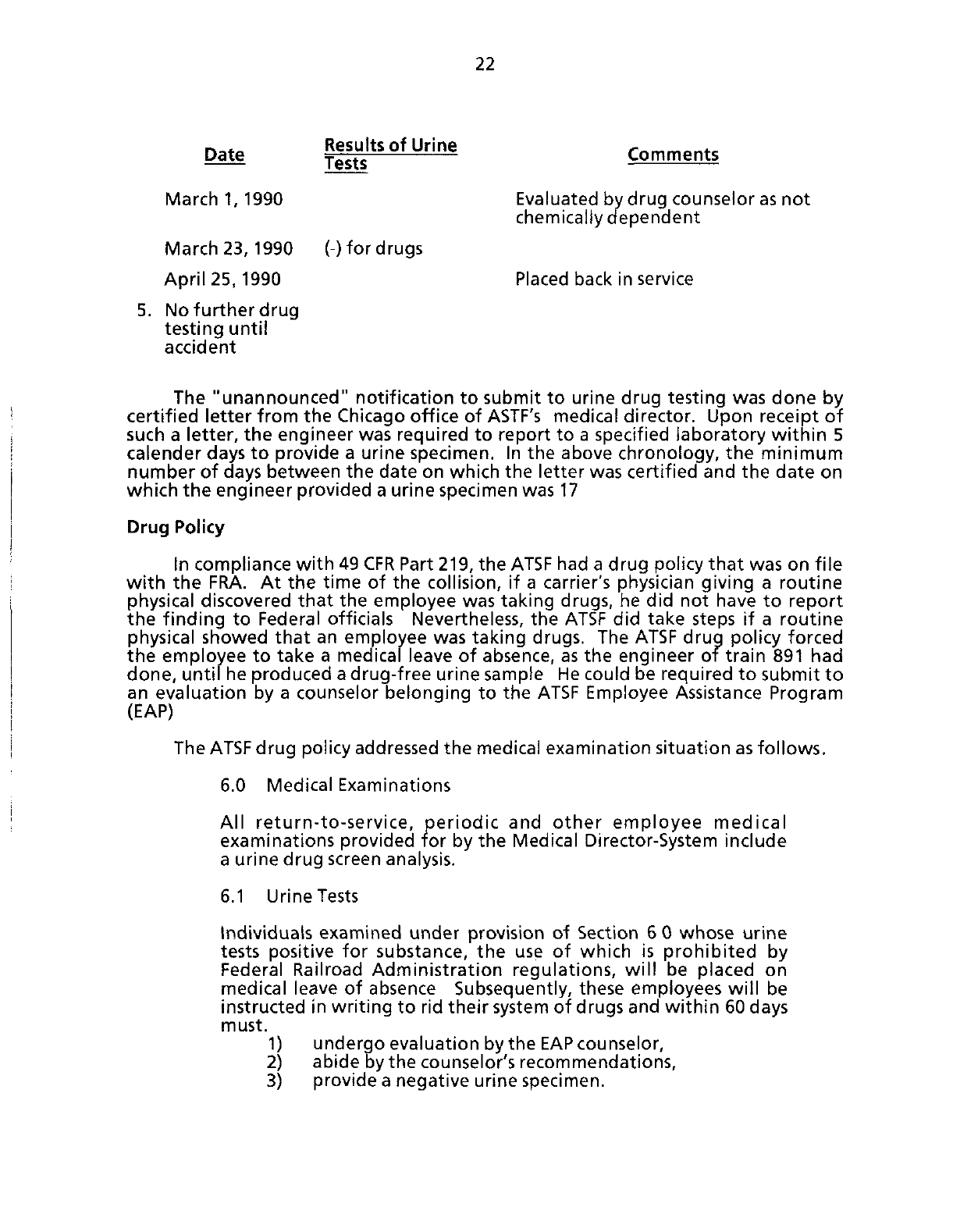

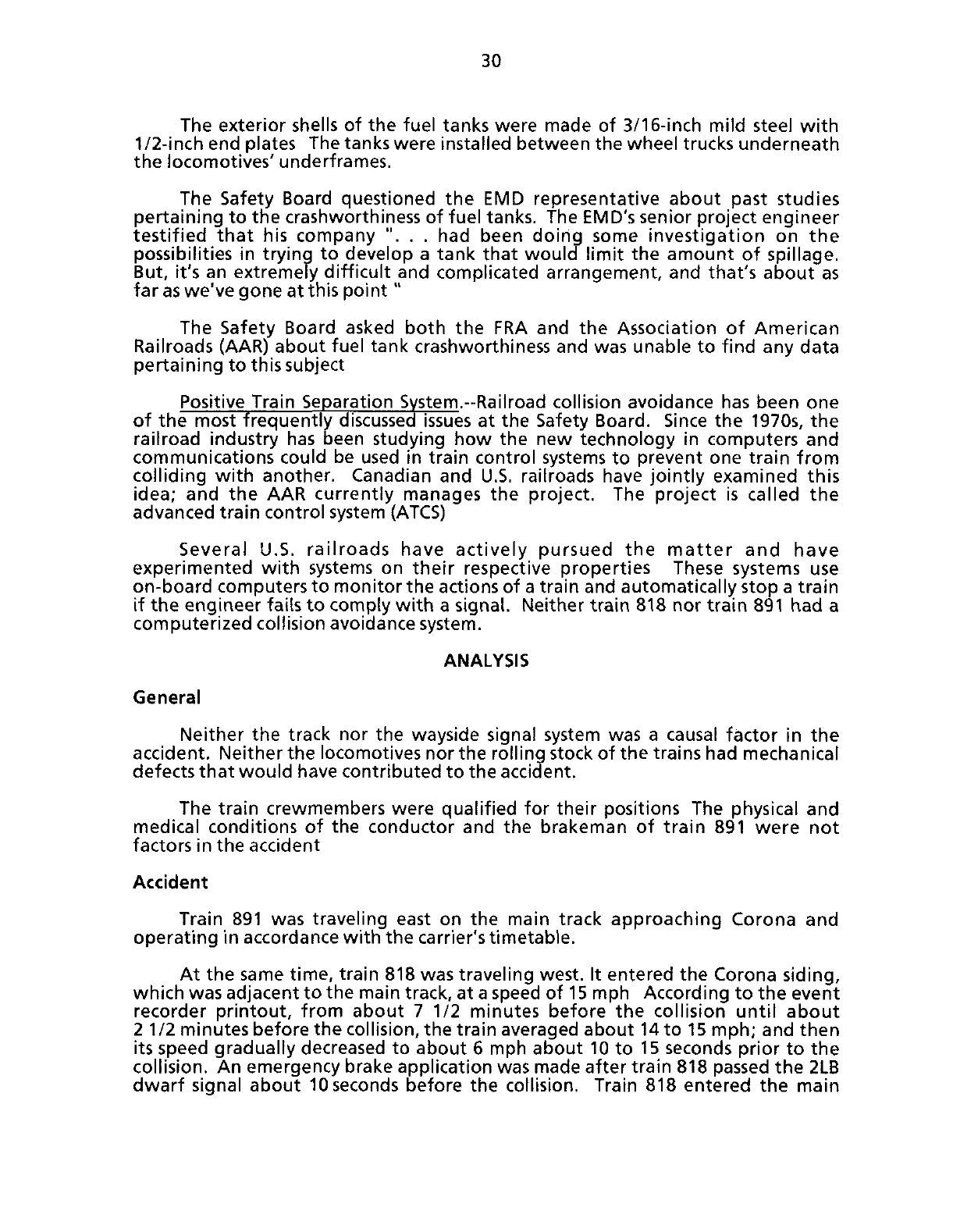

Chart

Of

The

Reporting Times

For The

Engineer

On ATSF 818

From

September

1,1990

Through

November 6,1990.

Last Day Worked

2400

2200

-h

2000

T

1800

w

1600

E

H

w>

1400

.5

§,

1200

v

Pi

iooo

• ;

osoo

-

\

0600

- •

0400

- ;

0200

T

0001

•

•

•

•

•

j_»

1111111111111111111 i 111111;

11111111

i f 11 1111 • 11111 • 111 • i 11 111 {1111

1-Sep

6-Sep

11-Sep 16-Sep 21-Sep 26-Sep

Source: ATSF Files

1-Oct

6-Oct

11-Oct 16-Oct

Dates Called

For

Work

21-Oct 26-Oct 31-Oct

Chart By NTSB

6-Nov

5-Nov

10-No

Figure

4.-- Reporting times for the engineer of train

818

from

September through November 1990.

15

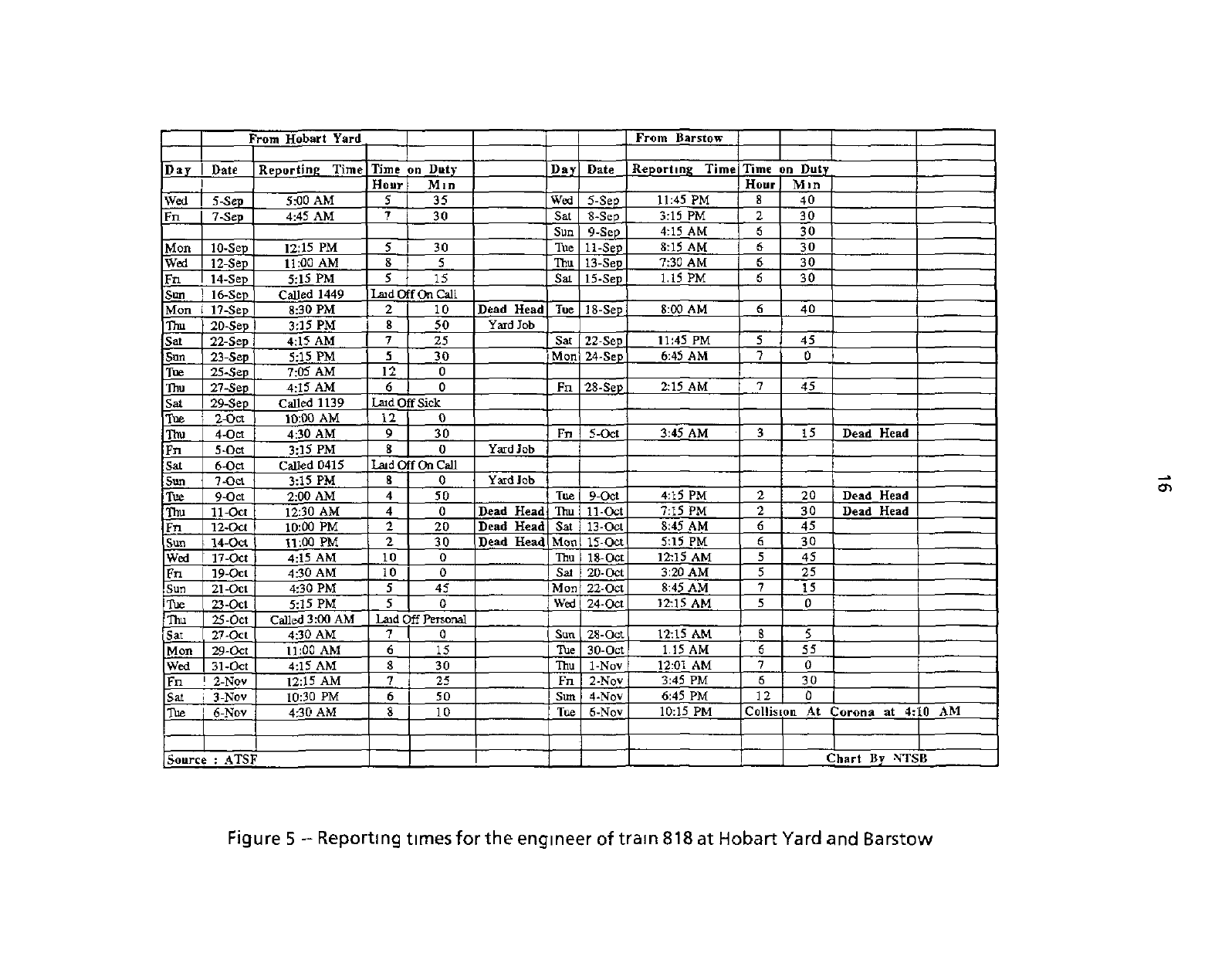

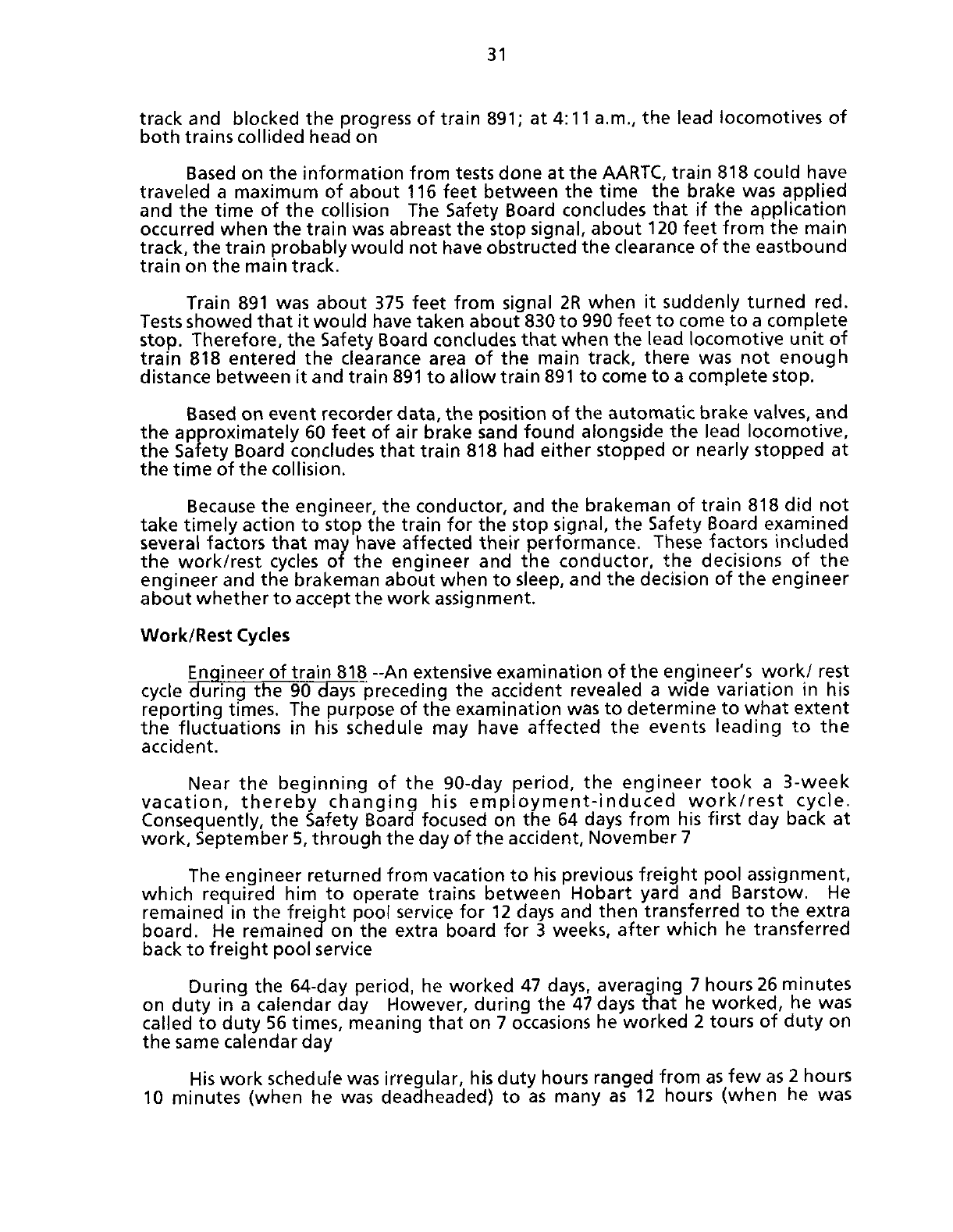

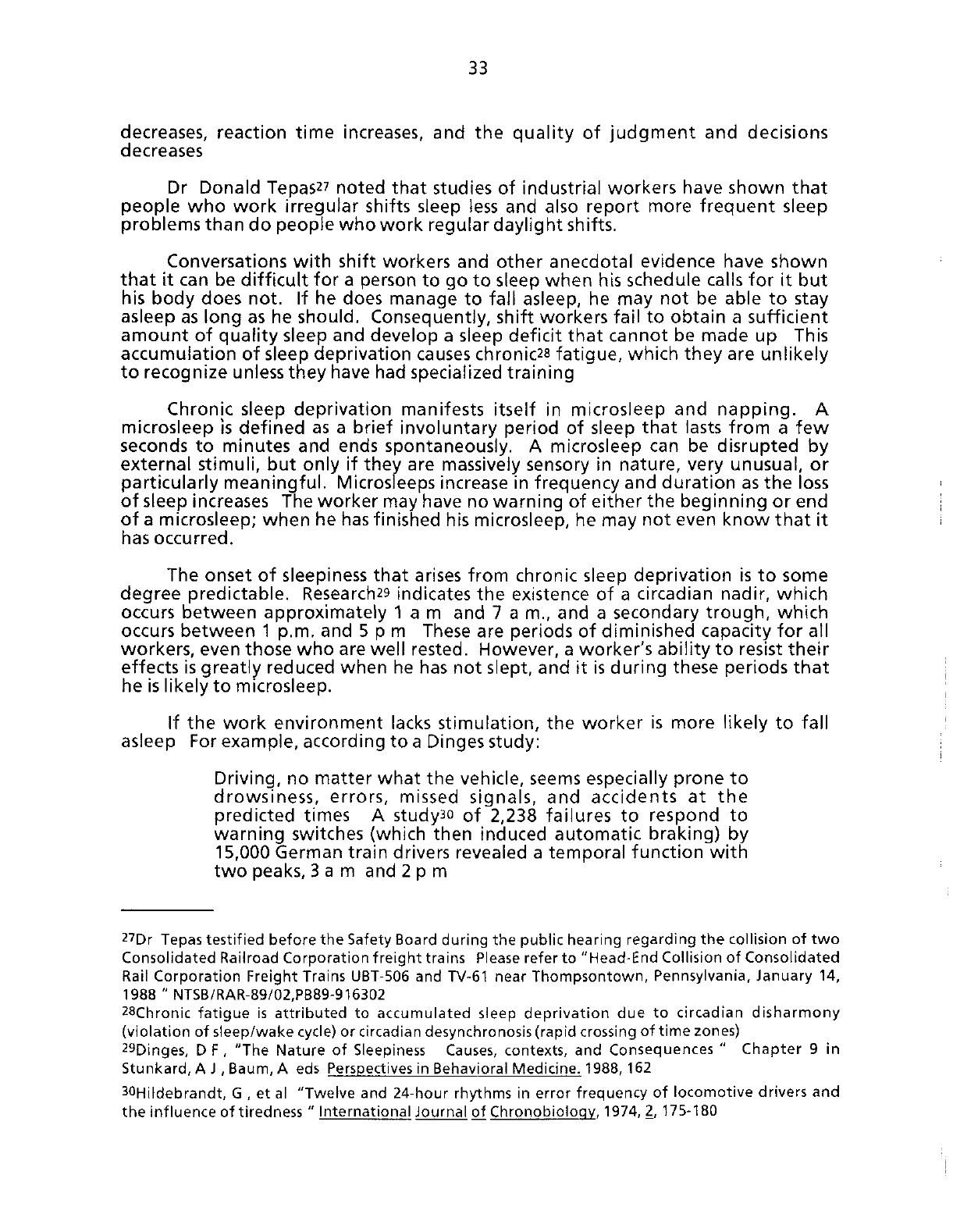

33 minutes Figure 5 shows the engineer's reporting times at both Hobart and

Barstow

yards.

Figure

4 illustrates the variation in his reporting time during the 64

days

before

the accident On April

1,1989,

Hobart yard became the home terminal for operating

personnel,

including the engineer of train 818, whose home terminal had been San

Bernardino

He continued to live in the San Bernardino area; his commuting time

increased

from 10 or 15 minutes to, depending on the traffic,

1

1/2 to 2 1/2 hours.is

When

he was in Barstow, he stayed at an ATSF-contracted motel about

5

minutes away from the terminal. He received his

calls,

on the average,

1

hour 5 minutes before his reporting time.

Operations.--The

ATSF

is among the 41 railroads that are signatories of the

General

Code of Operating

Rules.

(See appendix C for a listing of the rules referred

to in this report that are in the General Code )

At

San Bernardino, the main track split into the San Bernardino and Pasadena

subdivisions,

which were reunited at

Los

Angeles.

The

ATSF

manager of operations

(MOP)

testified that an average of 18 to 20 freight trains and 2 Amtrak passenger

trains traveled through the Corona station area in a

24-hour

period. Through

trackage rights agreements, both Amtrak and Union

Pacific

Railroad trains traversed

the

San

Bernardino subdivision east of Riverside

According

to the

ATSF

timetable, the maximum authorized speed for freight

trains on both the Cajon and the San Bernardino subdivisions was 55 mph On both

subdivisions

a train was restricted to 45 mph if it either weighed more than

7,000

trailing tons or had more than an average of 90 tons per operative brake.

Train 818 had a total of 8,616 trailing tons.

The Corona siding paralleled the main line for the siding's entire length,

8,507

feet. The

ATSF

timetable showed the Corona siding with

8,370

feet of

clearance^

available for safe train operations.

The Corona siding was intersected by four grade

crossings.

(See figure 1 ) The

first was Main Street, which was 565 feet from the east switch. The second was

Sheridan

Street, which was 1,786 feet from the east switch The third and fourth

were

Cota Street and Railroad Avenue, which were, respectively, 2,914 feet and

8,272

feet from the east switch

According

to the

ATSF

timetable, the authorized speed through the Corona

siding was 15 mph.

The General Code of Operating

Rules

specifies the actions that are to be taken

when one train is met or

passed

by another. Rule 89 states that "when a train is met

iSBecause

employees

living

in San

Bernardino

had so far to

travel

and because

traffic

congestion

in

the Los

Angeles

area

was

often

so bad, the

carrier

tried

to

give

employees

called

for

duty

at

Hobart

yard

2 1/2 to 3

hours

notice

of

their

reporting

times

The

engineer

of

train

818

received

his

calls

when

he was

home

2

hours

32

minutes,

on the average,

before

his

reporting

time

iSThe

clearance

is the

area

in

which

rolling

stock

and

locomotives

can

safely

clear

structures

and

equipment

on

adjacent

tracks

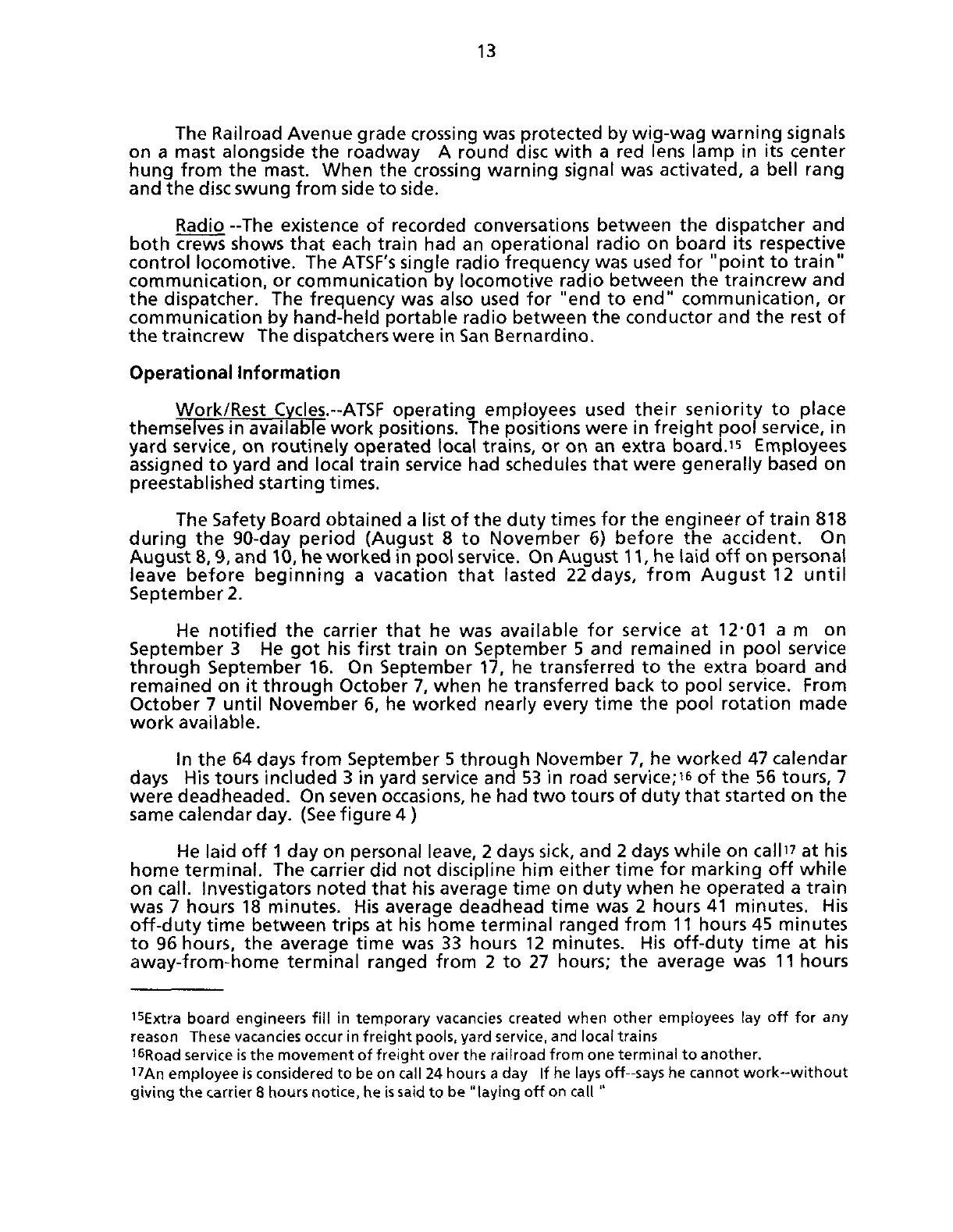

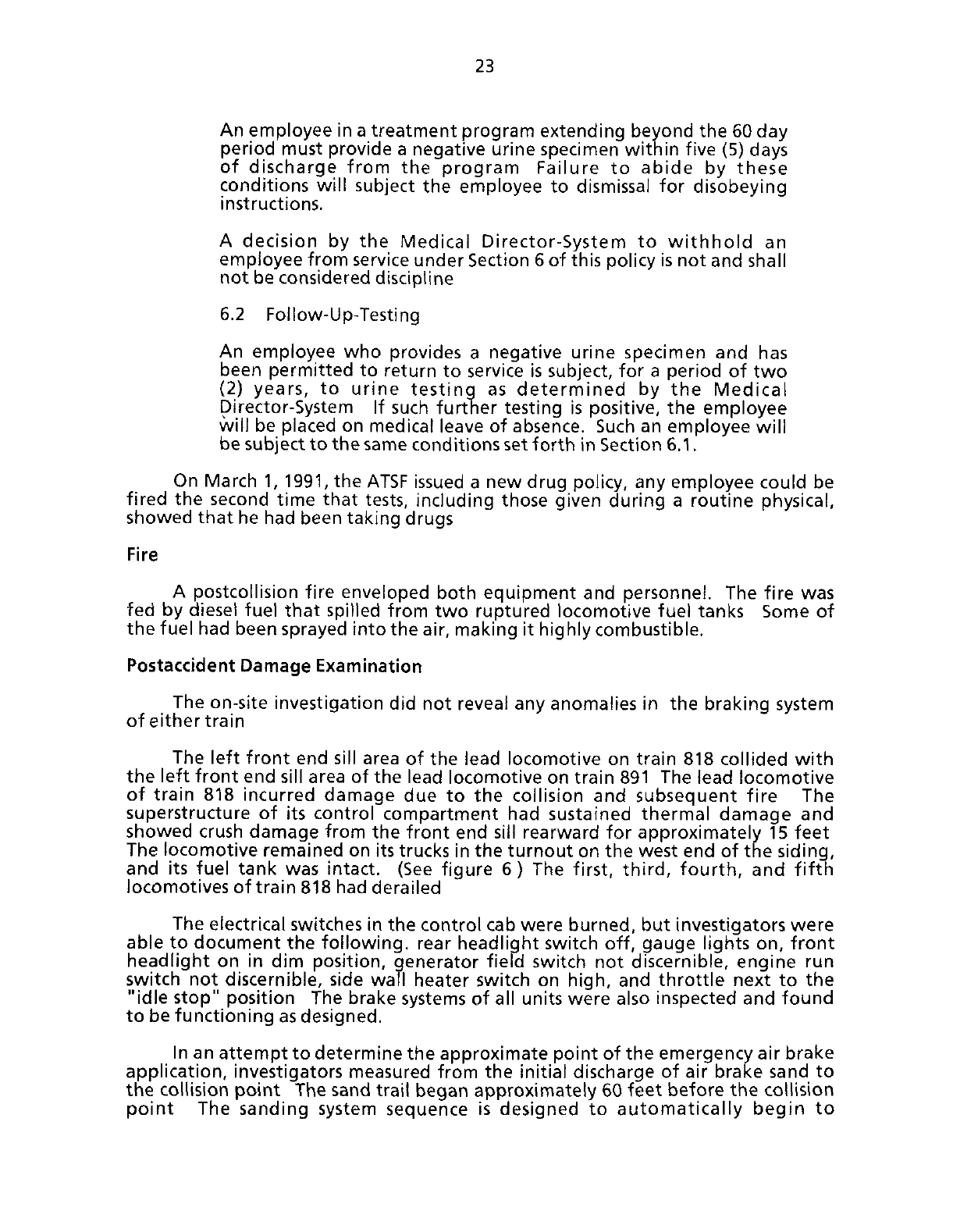

From Hobart Yard

From Barstow

Day

Date

Reporting Time

Time

on Duty Day

Date

Reporting Time Time on Duty

Hour Mm

Hour Min

Wed

5-Sep

5:00 AM 5

35

Wed

5-Sep

11:45 PM 8 40

Fn

7-Sep

4:45 AM

7

30 Sat

8-Sep

3:15 PM 2 30

Sun

9-Sep

4:15 AM S 30

Mon

10-Sep 12:15 PM 5 30 Tue

11-Sep

8:15 AM

6 30

Wed 12-Sep 11:00 AM

8

5 Thu 13-Sep

7:30 AM 6

30

Fn

14-Sep 5:15 PM

5

15 Sat 15-Sep

1.15 PM 6 30

Sun ! 16-Sep

Called 1449 Laid Off

On

Call

Mon i 17-Sep

8:30 PM 2

10

Dead Head Tue

18-Sep

8:00 AM

6 40

Thu

20-Sep 3:15 PM

8

50

Yard Job

Sat 22-Sep 4:15 AM

7

25

Sat

22-Sep

11:45 PM

5 45

Sun

23-Sep 5:15 PM

5

30 Mon 24-Sep

6:45 AM

7

0

Tue

25-Sep

7:05 AM 12 0

Thu

27-Sep

4:15 AM 6 0 Fn

28-Sep

2:15 AM

7

45

Sat 29-Sep

Called 1139 Laid Off Sick

Toe

2-Oct

10:00 AM

12 0

Thu

4-Oct

4:30 AM 9 30 Fn

5-Oct

3:45 AM

3 15

Dead Head

Fn

5-Oct

3:15 PM

8

0

Yard Job

Sat

6-Oct

Called 0415

Laid Off On Call

San

7-Oct

3:15 PM

8

0

Yard Job

Tue

9-Oct

2:00 AM

4

50

Tue

9-Oct

4:15 PM

2 20

Dead Head

Thu

11-Oct 12:30 AM

4

0

Dead Head Thu 11-Oct

7:15 PM 2 30

Dead Head

Fn

12-Oct 10:00 PM

2

20 Dead Head

Sat

13-Oct

8:45 AM 6

45

Sun

14-Oct

11:00 PM

2

30 Dead Head Mon

15-Oct 5:15 PM

6

30

Wed 17-Oct

4:15 AM 10 0 Thu

18-

Oct

12:15 AM 5 45

Fn

19-Oct 4:30 AM

10

0

Sat

20-Oct

3:20 AM

5

25

Sun 21-Oct

4:30 PM 5

45

Mon 22-Oct 8:45 AM

7 15

Tue 23-Oct

5:15 PM 5 0 Wed 24-Oct

12:15 AM 5

0

Thu 25-Oct Called 3:00 AM

Laid Off Personal

Sat 27-Oct 4:30 AM

7 0 Sun 28-Oct

12:15 AM

8 5

Mon

29-Oct 11:00 AM

6

15

Tue 30-Oct 1.15 AM

6

55

Wed

31-Oct 4:15 AM

8

30 Thu

1-Nov 12:01 AM

7

0

Fn

1

2-Nov

12:15 AM 7 25 Fn

2-Nov

3:45 PM 6 30

Sat i

3-Nov

10:30 PM

6 50 Sun

4-Nov

6:45 PM 12 0

Tue

6-Nov

4:30 AM S 10 Tue

6-Nov

10:15 PM

Collision At Corona at 4:10 AM

Source : ATSF

1

Chart By NTSB

Figure

5 -- Reporting times for the engineer of tram 818 at Hobart

Yard

and

Barstow

17

or passed

it

must stop and remain

not

less

than

400

feet from

the

signal

or

clearance

point

of

a facing point switch over which

a

train may

pass,

if

length permits."

In accordance with part

217.9 of

Title

49 of the

Code

of

Federal Regulations

(CFR),

the

ATSF

had

an

efficiency testing policy

for

testing operations employees

on

their knowledge

of

and compliance with its operating rules, timetable information,

and special instructions.

The

policy included guidelines

for 35

different

tests,

5 of

which

were about restrictive blocks

and

interlocking signals

One of the

tests

included operating rule

34,

"Observe

and

Call

Signals,"

which required

crewmembers

to

call signals

to

each other when they rode

in the

controlling

locomotive

According

to the

ATSF

regional manager, "most supervisors were required

to

make efficiency tests each month."

In

1990, supervisors in the subdivision performed

9,000

efficiency tests. About

10,000

trains traversed

the

subdivision during

that

period

of

time.

The

regional manager said

that

25

percent

of the

tests were

performed

at

night

All

crewmembers involved in the accident, with the exception

of

the brakeman

on train

818,

had been tested during the year before the collision. The engineer had

taken

76

tests He passed all

of

them, including two

that

were restrictive block signal

tests.

The conductor

of

train

818

had taken

24

tests with no failures.

The

engineer

of train

891 had

taken

36

tests, with

3

failures;

the

conductor

had

taken

70

tests,

with 1 failure; and

the

brakeman had taken

54

tests, with

3

failures. Cumulatively,

the five employees had taken

260

tests

ATSF

maintained hours-of-service records

for

all crewmembers involved

in the

accident. These records were in compliance with

49

CFR

Part

228.11.

The

ATSF

MOP testified

that

the carrier attempted

to

post

a

list

of

trains going

on duty on

a

4-hour

rotation via the

ATSF

system called

VIPS

The

ATSF

tried

to

have

the train line-up rotation information available

at 1, 5, and 9am and 1, 5, and

9

pm.

The

ATSF

regional manager testified

that

on

November

6, the

STO decided

on

the train line-up from Barstow

to

Hobart

at 4:17 p.m

and decided which crews were

to

be

deadheaded

at 515 p m.

The STO testified

that

on Tuesdays, and sometimes

on

Wednesdays,

crews were "invariably deadheaded due

to

traffic

cycles."

The crew calling office listed

on

VIPS

those crews being deadheaded

at

5.28 p m

The engineer

for

ATSF

818

had last checked the crew board when he went

off duty

at 12 40 p.m

By

contractual agreement,

the

ATSF

was required

to

issue "penalty

pay" to

employees

that

were held

at

their away-from-home terminal

16

hours beyond

the

time they went

off

duty.

The

carrier tried

to

avoid this occurrence whenever

possible.

Rule

G

of the

General Code stipulated

the

carriers' prohibition

of

alcohol

and

narcotics

on their property.

See

appendix

C

for

a complete definition

of

the rule.

18

Meteorological Information

According

to the

National Weather

Service,

the

ambient

air

temperatures

ranged from

56o

F

to 61o

F

at the

time

of the

collision Winds ranged from

12 to

19

mph; gusts ranged from

to 21 to 25 mph.

Temperature readings

and

wind

observations were taken

at

the three airports nearest the accident site

A

security guard who had been near the scene

of

the accident reported

on

local

wind conditions He described winds from

the

northeast

at 0 to 30

mph, "gusting

on

and

off

and blowing

a

lot

of

dust."

The conductor

of

train

891

indicated

it

was clear and breezy

in the

vicinity

of

the accident When specifically queried about the presence

of

blowing dust, he

said,

"I

don't believe so There might have been some,

but not

enough

to

obstruct

the

visibility."

He

reported

that

blowing dust was

not an

obstacle

to his

seeing

the

signal.

Also

interviewed were responding police officers,

who

reported

a

clear night

with

a

breeze Neither officer noted

that

his

vision

of the

collision scene

was

impaired by dust

Medical

and

Pathological Information

ATSF

818

Engineer.-According

to the

ATSF

medical files,

the

engineer received

his

last

physical

examination

on

March

23, 1990 He was

physically

fit for

duty

and was

issued

a

class

I

(unrestricted) medical certificate

As

part

of his

last

two

physical

examinations, his urine was screened

for

drugs, none were found

His

uncorrected

vision

was

20/15

(distant) and

20/10

(near),

he

had normal color vision

in

both

eyes

His

hearing was normal.

Conductor.-The conductor suffered from gastritis, which

he

had been treating

with

a

prescribed drug called Zantac

He

took

the

drug only

as

needed, which,

during

the

past

4

years,

was

infrequently.

He had

also suffered from headaches

during

the

past year, which his personal physician attributed

to

stress His wife said

that

he had not

been

ill

before

his

November

6

tour

to

Barstow,

nor had he

mentioned his health in the conversation he had with her while he was there

According

to the

ATSF

medical files,

the

conductor received

his

last physical

examination on April

19,1990

He was physically

fit for

duty and was issued

a

class

I

(unrestricted) medical certificate During

his

last

two

physical examinations,

his

urine was screened

for

drugs, none were found. His

vision,

corrected through

the

use

of

glasses,

was

20/20, he had

normal color vision

in

both

eyes

His hearing

was

last tested

on

October

5, 1989, he had

difficulty hearing high frequency sounds.

According

to

the

ATSF

medical director,

the

conductor's hearing was

not

outside

the

standards set by

the

American Academy

of

Audiolaryngology and

did not

preclude

him from performing his duties.

Brakeman.-The

ATSF

medical files indicate

that

she received

her

last physical

examination

on

October

17, 1990

She was physically

fit for

duty and was issued

a

class

I

(unrestricted) medical certificate During

her

last physical examination,

her

urine was screened

for

drugs, none were found

Her

uncorrected vision was

20/20

19

(near) and

20/22

(distant) Her color vision in both

eyes

was normal. She had a

hearing test on October

25,1990,

and

was

found to have normal hearing

ATSF891

Engineer.-The

ATSF

medical files indicate

that

the engineer received his last

physical

on March 23, 1990. He was found physically fit for duty and was issued a

class

I (unrestricted) medical certificate As part of his last physical examination he

underwent urine drug screening; the results were negative His uncorrected vision

was

20/50;

corrected by

glasses,

it was

20/20

in his right eye and

20/25

in his

left

eye.

He

had normal color vision in both

eyes

During his last hearing test, a slight

difficulty in hearing high frequency

sounds

was detected in his right ear.

Conductor --The conductor had reported

that

he was not sick on the day of the

accident.

He was taking two types of medicine The first was Ailopurinol, which was

prescribed for gout The carrier knew

that

he was using the drug The second was

Motrin, an over-the-counter drug, which he took for his arthritis. He had taken his

normal dose of Ailopurinol on the day of the accident and had taken a half dose (400

mg) of Motrin about 4 hours before the accident

According

to the

ATSF

medical records, his last medical examination was on

January

2, 1990. He was in good health and was issued a

class

I (unrestricted)

medical certificate His distance vision was

20/20

uncorrected in his

left

eye and

20/25

uncorrected in his right eye, his color vision was normal in both

eyes.

He had

difficulty hearing high frequency

sounds

with his

left

ear The examination included

a drug

screening,

and the results were negative.

Brakeman

--According to the

ATSF

medical file, he had his last physical on

November 7, 1989. He was physically fit for duty and was issued a

class

I

(unrestricted) medical certificate. His drug screen was negative. His uncorrected

vision

was

20/20,

and he had normal color vision in both

eyes.

His last hearing test

indicated

that

he had some difficulty hearing high frequency sounds with his

left

ear

Injuries

Fatal

--According to the Riverside County coroner's office, the three

crewmembers on train 818 died from smoke inhalation and thermal burns. The

evidence

of smoke inhalation was "soot in the airways " The autopsy surgeon

further reported

that

the brakeman's blood was "cherry red," indicating "carbon

monoxide intoxication." The autopsy report on the fourth fatality, the brakeman on

train 891, stated

that

he died of a severe head trauma

The engineer of train 818 suffered extensive thermal burns, diffuse charring of

his

body, and asphyxiation by smoke inhalation. His body was found approximately

20 feet northeast of the right rear corner of train 818's first locomotive.

The conductor of train 818 suffered extensive thermal burns, charring of his

entire body, and asphyxiation by smoke inhalation He had multiple injuries,

including lacerations of the liver, fractures of the right third through tenth ribs,

contusion

of the right lung, and subdural and subarachnoid hemorrhages His body

was

found about 15 feet west of train 818's lead locomotive on the south side of the

main track.

20

The brakeman

of

train

818

suffered extensive thermal burns, charring

of her

body,

and

asphyxiation

by

smoke inhalation.

Her

body was found about

20

feet

west

of

train 818's lead locomotive on the south side

of

the main track.

The brakeman

on

train

891

suffered

a

fracture

to the

base

of the

skull, brain

stem contusion, subdural and subarachnoid hemorrhages, extensive thermal burns,

and charring

of the

body His body was found

in the

control compartment

of the

train's third locomotive unit

Survivors.-The

engineer

of

train

891

sustained

a

concussion,

an

open fracture

of

the

right kneecap,

and

lacerations

of the

head

and

face

The

conductor

of

train 891 sustained bilateral comminuted fractures

of

the distal

tibia

and

the

fibula,

resulting

in

both ankles being broken

Both

surviving crewmembers were

hospitalized.

Toxicology

for

Drug Testing

In compliance with

49

CFR Part

219,

subpart C, blood and urine samples were

collected

from

the

survivors

of

train 891 and from the

ATSF

dispatcher

In

addition,

tests

were conducted on those who died.

The toxicology

on the

fatally injured crewmembers was reported

by

BioTox

Laboratory.

The carboxyhemoglobin (COHb) levels

in

three

of

the crewmembers

of

train

818

were

less

than

5

percent saturation;

in the

crewmember

of 891, it was

6 percent BioTox Laboratories sent the blood specimens

to

Poison

Laboratory, Inc

,

a clinical laboratory,

for

COHb analysis. According

to

telephone conversations with

the chief toxicologist

at

Poison

Laboratory, he was unaware

that

the specimens were

from fatally injured persons or

that

they were victims

of

a fire.

Blood

and

urine from

all

crewmembers and tissue specimens from

the

fatally

injured were sent

to

CompuChem Laboratories

to be

tested

for

drugs.

In

addition,

the Safety

Board

sent blood

and

urine from

all

crewmembers

to the

Center

for

Human Toxicology (CHT) Neither laboratory found

any

evidence

that

any of the

fatally injured crewmembers had taken illegal drugs.

CompuChem reported

that

the

urine taken from

the

conductor

of

train

891

contained

2,430

ng/ml

of

morphine

No

morphine was found

in his

blood.

The

conductor

had

received morphine

for

pain between

8 am. and 9.35 a m. on

November

7.

His blood

and

urine samples were collected

at

about

1 p m.,

almost

9 hours after

the

accident The CHT detected

a

morphine concentration

in

his urine

of

12,000

ng/ml Using

a

cut-off level

of 40

ng/ml,

it

did

not

detect morphine

in his

blood.

Blood

and

urine were collected from

the

engineer

of

train

891 at

about

3:30

p.m.,

11

hours after

the

accident CompuChem reported

that

his

urine

was

positive

for

methamphetamine

and

amphetamine

at

concentrations

of 457

ng/ml

and

88

ng/ml, respectively

At

the methamphetamine cut-off level

of 50

ng/ml,

his

blood

was

negative.

The CHT

reported

that

his

urine contained

587

ng/ml

of

methamphetamine,

117

ng/ml

of

amphetamine, and

8

ng/ml

of

the acid metabolite

of marijuana. Although CompuChem analyzed his blood, CHT did

not

have enough

of his blood

to

analyze.

21

The medical file on the engineer

of

train 891 revealed

that

his urine had tested

positive

for

marijuana

and

methamphetamine

on

three occasions before

the

accident.

The following chronology on drug testing results was constructed from

his

medical file.

Date

Results

of

Urine

Tests

Comments

1

April

7, 1988

(-f-)forTHC,

Amphetamine, and

Methamphetamine

April

22,1988 (-) for

drugs

April

28,1988

2

Dec 14, 1988

Feb

22, 1989

Feb

24, 1989 (-)

for drugs

3 June

15,1989

July

27, 1989

July

31,

1989

(

+

)forTHC

August

7, 1989

August

15, 1989 (-) for

drugs

August

18, 1989

August

28, 1989

4

Dec 5, 1989

Dec

19, 1989

Dec

22, 1989

(

+

)

for THC

Jan

2,1990

Feb.

13, 1990

Required

to

submit drug-free urine

within

90

days

Returned

to

duty on condition

that

he

submit

to

being randomly tested

fordrugs, timing would

be

announced

to

him by certified mail

Placed

back in service

Requested

by certified letter

to

have

urine tested

Accepted

hand-delivered certified

letter

Requested

by certified letter

to

have

urine tested

Accepted

hand-delivered certified

letter

Put

on medical leave and required

to

produce drug-free urine in

90

days

Evaluated

by

EAP

counselor

as

not

chemically

dependent

Placed

back in service

Requested

by certified letter

to

have

urine tested

Hand delivery

of

certified letter

Required

to

provide drug-free urine

within

90

days

Put

on medical leave

Provided

urine but specimen

container broke during shipment

22

Date

Results

of

Urine

Tests

Comments

March

1,1990

Evaluated

by drug counselor as

not

chemically dependent

March

23,1990 (-) for